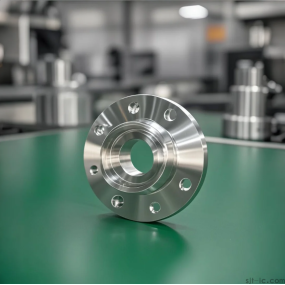

With the gradual development of the processing industry, the requirements for product quality and accuracy are becoming increasingly strict, and the difficulty of products is increasing. More and more problems need to be solved, and the large stroke five axis linkage processing has solved many difficult problems. If traditional three-axis gantry machine tools are used to process high-precision large parts, it is already laborious in terms of clamping, and the clamping side will be even more difficult to handle when encountering areas that cannot be processed. The first reason is that the object is too large to be clamped on the machine, and the clamping time is too long. It is really difficult to handle structures that are difficult to process.

And the large stroke five axis linkage machining has dealt with many difficult problems. The large stroke five axis linkage only requires one clamping to machine five surfaces, which solves the problem of multiple clamping by NC operators and reduces most of the pressure on NC operations. Secondly, regarding the difficult to machine orientation, the viewpoint of the workpiece can be changed to create cutting conditions for the tool, which can also shorten the length of the tool, avoid tool bouncing during processing, reduce tool resistance during use, extend the tool's service life, and save tool costs. Z is important for dealing with the difficulty of machining large and complex workpieces on the side, and many local five axis machines that are difficult to machine can handle irregular surfaces and turbine shaped workpieces with inclined hole structures. These are machining problems that five axis linkage machine tools can handle for the manufacturing industry, so five axis linkage machining is worthy of wide application.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque