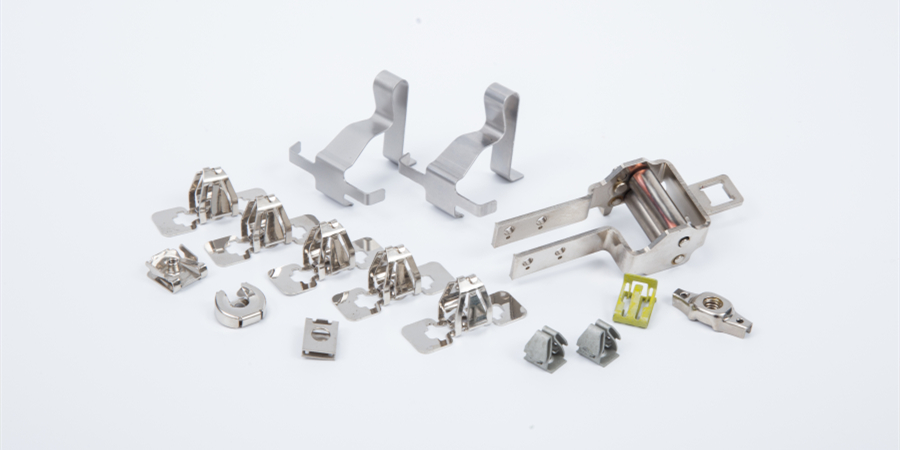

In the process of processing hardware parts in stamping factories, the raw materials used are closely related to stamping production, and the quality of materials directly affects the planning of stamping process, stamping part quality, product service life, and stamping part cost. Therefore, in order to stably produce excellent Metal Stamping parts, the raw materials used for stamping should meet certain performance requirements to adapt to the deformation requirements during the stamping process.

1、 The strength limit is the ability of metal materials to resist deformation and cracking under external forces. Commonly used strength limits include:

1. Yield limit: refers to the ratio between the metal material and its original cross-section under the effect of external force;

2. Tensile strength: refers to the ratio between the maximum tensile force that a metal material can withstand and its original cross-section;

3. Shear strength: refers to the maximum stress at which a metal material will not be damaged under the force effect of shear. The performance of metal materials that undergo permanent deformation under external forces without causing damage is called plasticity. The commonly used plasticity indicators are:

1. Elongation: When a metal material cracks under tensile force, the percentage of its elongation to its original length is called elongation;

2. Shrinkage rate of section: The percentage of the area where the section of a metal material shrinks to its original length when it cracks under tensile force is called the shrinkage rate of section;

3. Cup protrusion test value (stamping depth): The stamping processing factory has a standardized ball head punch on the cup protrusion test machine to uniformly press the plate sample. With the punch pressing down, a circular depression appears on the plate sample, and its depth continues to increase until a crack that can penetrate light appears. At this moment, the indentation depth is the cup protrusion test value.

3、 Hardness: The resistance of a metal material to being pressed into it by a harder object is called hardness. Hardness is an inductive physical quantity of material properties, representing the ability of a metal to resist elastic deformation, plastic deformation, or fracture within a small volume range.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque