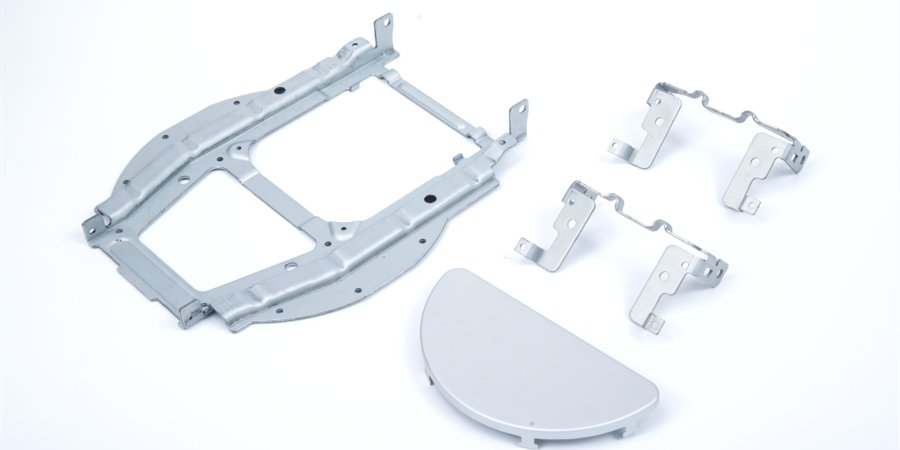

Briefly describe the technical requirements for mechanical processing in stamping factories:

1. Tolerance requirements

In the process of mechanical processing, it is necessary to meet the specifications and requirements for unmarked shape tolerances. The length error should be within 0.5mm, and the casting tolerance zone should be symmetrical. The fundamental size equipment of the blank casting should meet the relevant requirements.

2. Requirements for Cutting Processing Parts

Parts requirements are inspected and tested according to the process. However, it should be noted that only after passing the inspection in the previous process can it be transferred to the next process. It is important to note that burrs are not allowed on the processed parts. When placing precision machined parts, it is important to note that they cannot be placed directly on the ground and require support and maintenance. There should be no rust or damage on the ground that could affect functionality, resulting in scratches, dents, or other defects that may affect lifespan or appearance. Attention should be paid to the appearance requirements for processing, and there should be no compression or detachment. After the heat treatment process, there should be no oxide skin on the surface, especially on the cooperating surface after precision machining. The tooth surface should not have annealing conditions. After mechanical processing, there should be no defects such as black skin or bumps on the surface of the thread, which stamping processing factories must pay attention to.

Mechanical processing for machine production includes the transportation and storage of raw materials, preparation for production, production of raw materials, processing and heat treatment of parts, assembly and debugging of products, painting and packaging, and other contents. The content of the production process is very extensive. Modern enterprises use the principles and methods of systems engineering to organize and guide production, viewing the production process as a production system with inputs and outputs. It can make the management of enterprises more scientific, making them more adaptable and competitive.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque