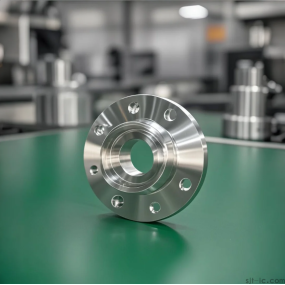

Shenyang Sheet Metal Processing is a commonly used metal processing method nowadays. In the process of machining parts, due to various factors such as machining accuracy of mechanical equipment, mold wear, and machining errors, the standards of the produced sheet metal parts cannot be guaranteed to be accurate. In order to ensure the usability of the workpiece, it is necessary to limit the tolerance of the sheet metal workpiece to a small value.

What are the common tolerance standards in sheet metal processing? How should it be symbolized? Today, the Weiyun editor will share with you. What are the tolerance standards for sheet metal processing? What standards are used for sheet metal processing tolerances? Confirm the standards confirmed in the plan based on the strength and structural requirements of the parts. Priority should be given to standard diameter or length.

Practice standards are standards obtained through measurement. The limit standard allows for two thresholds for size changes. It is based on the base size. The larger of the two boundary values is called the large constraint size; The smaller one is called the small bundle size. Algebraic difference obtained by subtracting the base criterion of a certain standard.

The standard error is as follows: upper and lower errors can be called limit errors, which can be positive, negative, or zero. According to national standard regulations, the upper error code for holes is ES, the lower error code is EI, the upper error code for shafts is ES, and the lower error code for shafts is EI

The content of the article is sourced from the internet. If you have any questions, please contact me to delete it!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque