Problems in CNC machine tool machining:

1. Improper computer programming

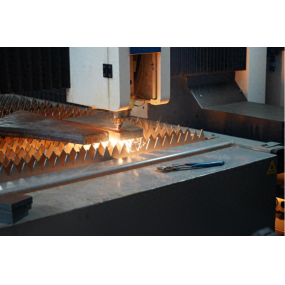

With the rapid development of computer science and technology, CNC machine tool machining is becoming increasingly intelligent. Currently, CNC machine tool machining is based on computer programming programs, which decompose the entire CNC machine tool machining work into multiple distributed control steps. Currently, computer programming programs are widely used in various aspects of CNC machine tool machining. At the same time, there are also redundant debugging processes and errors in CNC machine tool machining systems, such as running empty or wrong tools. The main reason for this problem is that computer programming is not standardized, and non-standard computer programs often make errors in the CNC machine tool machining process, seriously affecting the efficiency of CNC machine tool machining.

2. Lack of comprehensive and standardized industry systems

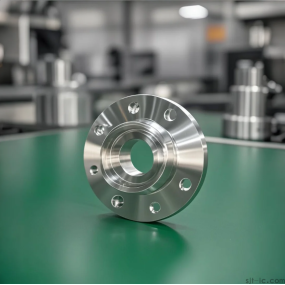

In recent years, the machining technology and processing systems of CNC machine tools have developed rapidly. However, the machining industry lacks a complete and standardized industry system to address the problem of difficulty in achieving the relevant accuracy of CNC machine tool machining parts due to equipment wear and tear. In addition, some operators do not have a comprehensive understanding and mastery of advanced CNC machine tool machining equipment, making it difficult to distinguish between precision machining and rough machining in terms of performance. This not only affects the quality of machining parts, but also affects the machining efficiency of CNC machine tools.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque