Imitation EMAR cabinet Sheet Metal Processing is a commonly used steel cabinet in offices, schools, and various commercial places, and its sheet metal processing is one of the important steps in manufacturing EMAR cabinets. In the process of sheet metal shell processing, some problems are often encountered. Below, the sheet metal processing manufacturer's editor will answer these common questions.

1. Which type of steel is suitable for sheet metal processing of EMAR cabinets?

For the production of EMAR cabinets, the steel commonly used for sheet metal processing includes cold-rolled steel plates, galvanized plates, and stainless steel plates. The specific choice of steel depends on the usage environment and requirements of the EMAR cabinet. Generally speaking, cold-rolled steel plates can meet most of the usage needs, while stainless steel plates are suitable for use in environments with high external surface requirements.

How to avoid sheet metal deformation during sheet metal processing?

During sheet metal processing, deformation of the sheet metal is a common problem. To avoid deformation of the board, the following points need to be noted:

-Control stamping force: During the stamping process, excessive stamping force can easily cause deformation of the sheet metal, so it is necessary to control the stamping force reasonably.

-Reasonable selection of molds: Choosing the appropriate mold can make the stamping process more stable and reduce the deformation of the sheet metal.

-Proper processing of sheet metal strength: By heat treatment or local cold processing during the sheet metal processing, the strength and stability of the sheet metal can be improved, and the possibility of deformation can be reduced.

How to deal with surface scratches after sheet metal processing?

In the process of sheet metal processing, surface scratches are difficult to avoid, but there are several methods to deal with surface scratches:

-Using a polishing machine for polishing: Using a polishing machine to polish the surface of the cabinet can eliminate or reduce scratches on the surface.

-Coating treatment: By coating the surface of the cabinet, scratches on the surface can be covered or repaired, resulting in a smooth effect on the cabinet surface.

-Regular maintenance: Regular maintenance and upkeep of the surface can reduce the generation and spread of surface scratches, and maintain the smoothness and aesthetics of the cabinet surface.

How to improve the efficiency of sheet metal processing?

The efficiency of sheet metal processing is very important for production enterprises. Here are several methods to improve sheet metal processing efficiency:

-Optimize production process: By optimizing the production process, arranging the production process reasonably, reducing production links, and improving production efficiency.

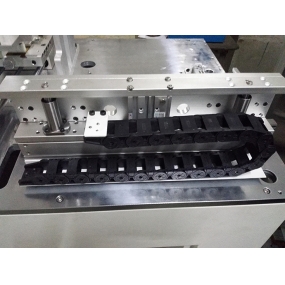

-Introducing automation equipment: Introducing advanced automation equipment can achieve production automation and improve production efficiency.

-Training excellent operators: Train operators to improve their operational skills and work efficiency, thereby enhancing the overall efficiency of sheet metal processing.

How to ensure product quality during sheet metal processing?

Ensuring product quality is the core goal of sheet metal processing. The following are several methods to ensure product quality:

-Strictly control the production process: from developing production plans to debugging molds, every link must be strictly controlled to ensure the quality of each link.

-Strictly control material quality: Conduct rigorous inspection and sampling testing on each batch of sheet materials to ensure that the quality of incoming materials meets the requirements.

-Regular equipment maintenance and upkeep: Regularly maintain and upkeep equipment to ensure its normal operation and reduce the production of defective products due to mechanical failures.

-Conduct comprehensive testing and quality control: Strict testing and quality control are carried out at every stage of sheet metal processing to ensure that the product meets quality requirements.

In short, sheet metal processing plays an important role in the production process of EMAR cabinets. Understanding the answers to common questions can help us better carry out sheet metal processing, improve product quality and production efficiency.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque