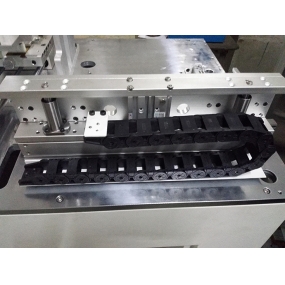

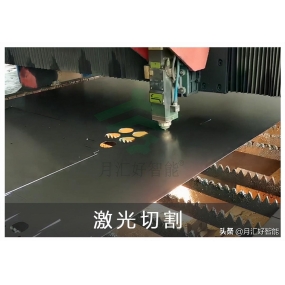

The Metal Stamping mold device is suitable for selecting a gathering device, and in the device process, repair and adjustment methods are often used to ensure the accuracy of the device. Thus, components with low precision can be used to achieve high device accuracy and reduce machining requirements. There are several skill requirements for the hardware stamping mold device in stamping processing plants, including the following aspects:

1、 Requirements for appearance skills of stamping molds:

1. The edges of each template and exposed parts of the stamping die after installation should be chamfered or rounded, so small as to have burrs and sharp angles; Each appearance must not have serious scratches, dents, or adhered dirt; There should also be no embroidery marks or partially unprocessed rough surfaces;

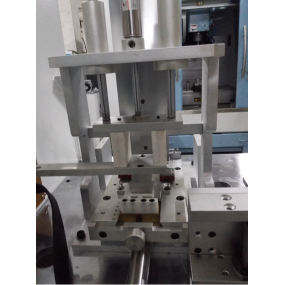

2. According to the working state of the stamping die, lifting rings or lifting rings should be installed at the appropriate balance position of the stamping die; The multi parting stamping die stamping processing plant applies locking plates to lock each stamping die to prevent damage caused by the movement of the template during transportation due to shaking;

3. The external dimensions, closure height, device alignment and positioning dimensions, ejection method, mold opening stroke, etc. of the stamping die should meet the requirements of the design drawings and be reasonably matched with the parameters of the equipment used;  4. Stamping molds should have marking numbers, and each template should be printed with sequential numbers and imprints of processing and device reference angles;

4. Stamping molds should have marking numbers, and each template should be printed with sequential numbers and imprints of processing and device reference angles;

5. The connecting screws of the stamping die's moving and fixed molds should be tight and secure, and their heads should not be higher than the template plane;

6. The various auxiliary organizations on the appearance of stamping molds, such as hooks, swing rods, locks, cooling water nozzles, hydraulic and electrical components that constrain the opening sequence, should be fully installed, standardized, and reliable.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque