Shenzhen EMAR Precision Technology Co., Ltd. is a professional manufacturer specializing in high-precision CNC machine tool external processing. Its products cover various fields including aviation, medical, communication, automotive, etc. Today, let's take a look at the star equipment in the field of mechanical processing, the globally renowned five axis gantry machining center (ranked in no particular order);

1、 Italian Breton Five Axis Linkage Longmen Machining Center TITAN

Breton machine tools from Italy have a high reputation in Europe, mainly due to their excellent production performance, top-level technical level, and pioneering solutions, which can provide customers with indisputable product quality and service systems.

2、 Spanish Doctorate BOST Longmen Five Axis Machining Center

The team of Doctor Special Services is a leader in the machine tool manufacturing market. They produce heavy-duty machine tools including vertical lathes, vertical turning and milling machines, horizontal turning and milling composite machines, floor boring machines, large gantry milling machines, railway industry specific machine tools, and provide turnkey projects.

The CNC gantry moving beam pentahedral machining center independently developed and researched by Docter Machine Tool Company is equipped with different specifications of CNC turning and milling workbenches for horizontal beam movement and gantry column movement, achieving a perfect combination of gantry and turning and milling center machining methods. After configuring the automatic positioning universal accessory head, the machine tool can achieve 7-axis CNC linkage machining. The machine tool is equipped with static hydraulic guide rails for all spools of the ultra large heavy-duty casting bed body. Its characteristic is that it has super strong shock absorption, ensuring high workpiece machining accuracy and efficient heavy cutting ability. Because it is a non-contact guide rail, its service life is longer than traditional linear guide rails.

The maximum X-axis stroke of the CNC gantry machining center currently developed by Docter Company is 21 meters, the maximum Z-axis stroke of the slider is 2 meters, and the maximum upper limit diameter of the turning and milling worktable is 4.5 meters. The maximum load-bearing capacity of the chuck is 100 tons, suitable for processing large, heavy, and high-precision workpieces. The machine tool is widely used in aerospace, military, and nuclear industry heavy-duty fields.

3、 MECOF, Italy

MECOF Italy is a subsidiary of EMCO, producing large gantry machining centers, large vertical machining centers, and floor boring and milling machining centers.

Product:

1. Longmen machining center MECOF/X5.5Y3Z1.5

Weight: 70000 (kg)

Spindle speed range: 24000 (rpm)

Three axis travel (X * Y * Z): 5500 * 3000 * 1500

Power type: electric

Layout form: Vertical

2. Longmen machining center DYNAMILL3000/L

Italian 5-axis linkage high-speed gantry machining center

Numerical Control System: CNCFidiaM20/MSG

Workbench: 5000mm * 3000mm

X-axis: 5500mm

Y-axis: 3000mm

Z-axis: 1500mm

Feed speed: 0-15000mm/min

Fast moving speed: 1m/sec

Three milling heads

Knife magazine: 12ISO50,12HSK63-A

4、 Handtmann five axis gantry machining center from Germany

The three major product series of Handmann five axis gantry machining centers in Germany cover a wide range of parts made of different materials: titanium, steel, aluminum, and composite materials, ensuring peak performance in accuracy, productivity, and cost-effectiveness.

1. HSC five axis PBZ? Contour machining center is a professional development for profile contour machining. Handtmann meets the highest requirements for precise and economical processing of profiles up to 30m in length from titanium, aluminum, steel, composite materials, and plastics.

Renowned manufacturers rely on Handtmann contour machining centers in the general metal processing industry, curtain wall industry, and aerospace industry.

Workpiece:

Floor crossbeam (composite) seat track (stainless steel) longitudinal beam (composite) seat track (aluminum)

2. The modular machine design of the HSC5 UBZ universal machining center allows for flexible and economical processing of parts with a maximum size of 12x2 meters from the following materials: titanium, steel, aluminum, composite materials, and plastics.

3. HSC 5-axis GANTRY? Longmen machining center is specially designed for processing large and heavy parts. The combination of three GANTRY models (VS/CS/TS) achieves maximum precision in economically processing titanium, steel, aluminum, composite materials, and plastics.

5、 German Fooke Longmen Five Axis Machining Center

FOOKE GmbH is a family owned enterprise founded in 1904 in Borken, western Germany. Fooke, a German company, has 30 years of experience in manufacturing large and ultra large high-speed five axis gantry milling machines. The machines are equipped with linear motors to achieve high-precision precision machining. Fooke has a very good reputation in the aerospace industry and also provides high-performance and high reliability machine tools to the railway, automotive, and other fields.

FOOKE has been working closely with multiple clients since the 1990s to jointly develop milling machines and production centers that can be delivered for use. Most modern high-speed trains and trams are made of large aluminum profiles and components. Large, fast, reliable, and especially sturdy and durable - features of the milling machine used for manufacturing rail vehicles.

Special requirements for the aerospace industry: minimization of tolerances and diversified combination of modern materials.

FOOKE can provide various milling machines and machining centers according to specific requirements for efficient cutting of aluminum and titanium products, as well as processing of CFK and other composite materials. Standard programs cannot meet customer needs, and FOOKE will work closely with them to design and develop production solutions that fully meet their requirements.

The requirements for model manufacturing, prototype manufacturing, tool manufacturing, and mold manufacturing can be summarized as surface quality and accuracy. In addition, it is necessary to process as many materials as possible on one machine tool or one machine tool - from hard foam to alloy tool steel, which is both economical and reliable. For this reason, FOOKE has launched a high-performance five axis milling machine.

6、 Zimmermann five/six axis gantry machining center from Germany

Zimmermann, a German company, has been committed to milling special profiles. Since its establishment in 1938, the company's business has mainly involved cutting and correcting the external contours of different materials, and has become a world leading manufacturer of high-tech gantry milling machines.

Zimmermann's gantry machining center in Germany has a strong foundation in many fields such as the automotive industry and aviation industry.

Zimmermann, a German company, has successfully achieved 6-axis machining through the use of gantry milling machine FZ100 and 3-axis milling head M3ABC. In the field of large cutting volume machining of aluminum alloys, model materials, composite materials, as well as HSC high-speed cutting of steel parts and cast iron, this machining concept solves the bottleneck of traditional 2-axis fork milling head 5-axis linkage machining. Advantages: 4x processing speed; Achieve perfect surface processing quality through 6 axes; Achieve the highest machining accuracy.

7、 German MIKROMAT high-precision 5-axis gantry machining center

MIKROMAT, a German company, has world leading technology in the field of precision machining. The Mikromat system ensures more precise and efficient manufacturing technology for its precision machining.

According to the diverse product production needs of different customers, MIKROMAT provides various industrial automation solutions that not only improve production efficiency, but also provide more improvements in processing methods and manufacturing processes.

8、 ZAYER Spain's gantry five axis machining center

ZAYER, a Spanish company, has been manufacturing boring and milling machines and machining centers in Victoria since 1947, accumulating 60 years of experience. The company's corporate spirit is to provide innovative capabilities to customers.

ZAYER's gantry five axis machining center from Spain has four major series: 1. NEOS; 2. MEMPHIS; 3. THERA (THERAW); 4. ARGUS (ARGUSW);

The MEMPHIS series gantry machining center is mainly used in the industries of aviation structural components, railway structural components, molds, and stamping dies.

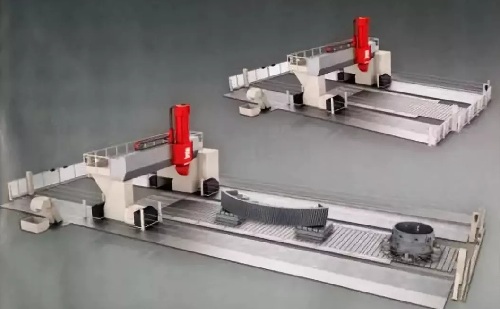

9、 Unisign Netherlands Longmen Processing Center

Unisign is a specialized machinery company specializing in the development, design of tools, fixtures, and metal cutting industries.

UNIPORT7000 has 5-axis machining capability, excellent rigidity and precision, as well as flexible and economical advantages, and is highly trusted by customers. UNIPORT7000 is an economical and flexible manufacturing solution. The innovative box type enclosed structure ensures excellent rigidity and highly stable and accurate production processes.

Dutch Unisign Longmen Machining Center Industry Case:

Aerospace: Jet Engine Steel Rings and Circles

Missile shell

Structural components: wing ribs, control valves, wing beams, longitudinal beams, triple eccentric butterfly valves, fuselage, tail fins, valve sleeves, partitions, pump casings;

Energy industry: planetary gearbox rings/seals, bearing seats

Turbine and generator components

Railway high-speed train industry: processing of railway bogie frame, preparation of steel plate welding, side and top plate train wheels;

10、 Reichenbacher Hamuel Longmen Machining Center ECO Series from Germany

Reichenbacher Hamuel, with its machining center ECO, has transferred its rich experience in the field of special machine tools to machine tool series with the highest flexibility and productivity. The ECO machine series also embodies the characteristics of all Reichenbacher Hamuel machine series, namely reliability, speed, and precision.

The vibration free gantry can drive one or more unit slides (optional on the back of the gantry) based on its size and worktable with 2 or 3 supports. The unit slides can move horizontally or vertically. According to production indicators, ECO can be equipped with one or two independent CNC channel control machining units. The basic machine tool is equipped with one or two movable machining workbenches.

In addition, additional workbenches can be installed to perform assembly procedures, during which the machine tool can still operate normally without affecting the feeding time in the exchange operation state. The workbench feeding can be performed from three sides. The production efficiency and availability are greatly guaranteed through different equipment options.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque