The process of CNC lathe machining is similar to that of ordinary lathes, but due to the fact that CNC lathes are one-time clamping and continuous automatic machining completes all turning processes, the following aspects should be noted:

1. Reasonably choose cutting parameters

The reasonable selection of cutting parameters (ap, f, v) plays an important role in fully utilizing the potential of machine tools and cutting performance of cutting tools, achieving high-quality, high-yield, low-cost, and safe operation.

When rough cutting, first consider selecting a maximum back cutting amount ap, then choose a larger feed rate f, and finally determine a suitable cutting speed v. Increasing the back cutting amount ap can reduce the number of cutting times, and increasing the feed rate f is beneficial for chip breaking. Therefore, selecting the rough cutting amount based on the above principles is beneficial for improving production efficiency, reducing tool consumption, and lowering processing costs.

During precision machining, high precision and surface roughness are required, and the machining allowance is small and uniform. Therefore, when selecting cutting parameters for precision machining, emphasis should be placed on ensuring machining quality and maximizing productivity on this basis. Therefore, during precision machining, a smaller (but not too small) back cutting amount ap and feed rate f should be selected, and cutting tool materials with high cutting performance and reasonable geometric parameters should be chosen to maximize the cutting speed v.

2. Reasonably choose cutting tools

1) When rough cutting, it is necessary to choose cutting tools with high strength and good durability to meet the requirements of large back cutting and feed rates during rough cutting;

2) When precision machining, it is important to choose tools with high precision and good durability to ensure the required machining accuracy.;

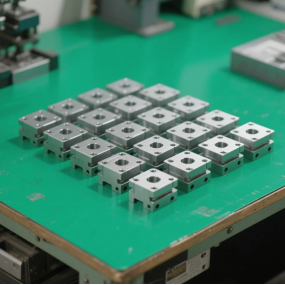

3) To reduce tool changing time and facilitate tool alignment, machine clamped knives and machine clamped blades should be used as much as possible.

3. Reasonably choose fixtures

1) Try to use universal fixtures to clamp workpieces and avoid using specialized fixtures;

2) Align the positioning benchmarks of the parts to reduce positioning errors.

4. Determine the processing route

The machining route refers to the motion trajectory and direction of the tool relative to the part during the machining process of the CNC machine tool

1) Should be able to ensure machining accuracy and surface roughness requirements;

2) Efforts should be made to shorten the machining route and reduce the tool idle time.

5. The relationship between machining route and machining allowance

At present, in the absence of widespread use of CNC lathes, excessive allowance on the blank, especially the allowance containing forged or cast hard skin layers, should generally be arranged for processing on ordinary lathes. If it is necessary to use a CNC lathe for machining, attention should be paid to the flexible arrangement of the program.

6. Key points for fixture installation

At present, the connection between the hydraulic chuck and the hydraulic clamping cylinder is achieved through a pull rod. The key points for clamping the hydraulic chuck are as follows: first, use a handle to remove the nut on the hydraulic cylinder, remove the pull tube, and extract it from the rear end of the spindle. Then, use a handle to remove the chuck fixing screw to remove the chuck.

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque