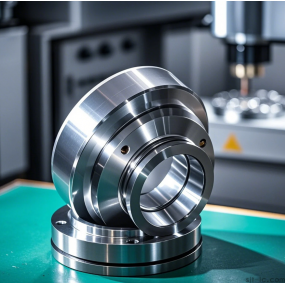

Errors are inevitable in Sheet Metal Processing in Shenyang. To ensure efficiency, reduce material waste, and decrease labor, it is necessary to ensure and improve processing accuracy. So, what are the ways to improve machining accuracy?

The original error reduction method: If there are any errors in production, the main factors affecting processing errors should be identified first, and then efforts should be made to eliminate or reduce these factors. For example, when processing parts with a shape appearance, the main focus is on reducing the shape error of the forming tool and the installation error of the tool.

Original error compensation method: artificially creating a new error to offset the original error in the process system. When the original error is negative, the human error is positive. Otherwise, take a negative value and try to make the two scales equal.

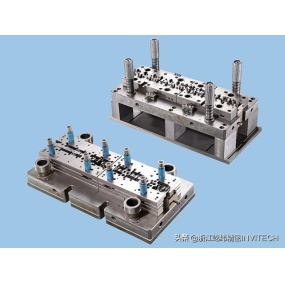

Raw error transfer method: Transfer the raw error of the machining system to the non sensitive direction of the machining error or other aspects that do not affect the machining accuracy under certain conditions. For example, when the accuracy of the machine tool cannot meet the requirements of part processing, it is possible to create conditions on the machining or fixture to transfer the geometric errors of the machine tool to aspects that do not affect the machining accuracy.

Original error balancing method: If the positioning error is large, differential method can be used. Divide the original error into n groups based on their size, reduce the error range of each group to 1/n of its original size, and then adjust the processing according to each group.

Raw error homogenization method: For parts with high machining accuracy, homogenization method can be used. It identifies differences through closely related appearances, and then corrects or benchmarks each other to reduce and equalize the errors in the appearance of the workpiece.

In mechanical processing, the accuracy of machining errors is inevitable. Only by analyzing the factors that affect errors can corresponding preventive measures be taken to reduce processing errors and improve processing efficiency.

The content of the article is sourced from the internet. If you have any questions, please contact me to delete it!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque