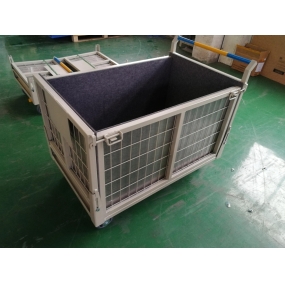

1. Box type components

Box type parts have always been a headache for parts processing enterprises due to their high processing difficulty, and the development and application of five axis machining machines for unmanned aerial vehicle parts have assisted many enterprises in dealing with this problem. It can use the repeated rotation of the workbench and the four sided machining skills in the horizontal direction to miraculously complete the machining of box type parts.

2. Disk cover plate parts

The five axis CNC Machining skills for unmanned aerial vehicle parts are particularly suitable for processing disk cover parts, which have key slots, radial holes, or scattered holes on the end face, such as flanged shaft sleeves, shaft parts with key slots, and various machine motor covers. When applying the five axis machining technique for these parts, both vertical and horizontal machining centers can be used, which needs to be confirmed based on the specific aperture.

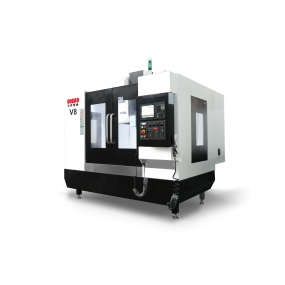

3. Special processing

According to many equipment experts' discussions, it has been found that the five axis CNC machining machine for drone parts can also complete certain special types of machining. Only specialized tooling, tools, and certain special processes are required to complete special machining, such as line scanning and quenching on the surface of metal parts. This type of machining used to have a high success rate, but now with the help of high-precision and high-performance five axis machining, the success rate has been greatly improved.

The deep processing capabilities of the five axis CNC machining skills for drone parts have caused significant vibrations in multiple industries. Many people have gradually verified this achievement through experiments on five axis machining of aviation parts. According to statistical results, five axis machining of drone parts is not only suitable for box type parts, disk cover plate type parts, and special machining, but also particularly suitable for machining irregular parts and irregular surfaces.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole