Sheet metal shell processing is a manufacturing process that uses sheet metal materials to create a specific shape of product shell by cutting, bending, stamping, welding, and other processes. Sheet metal shell processing has the following advantages:

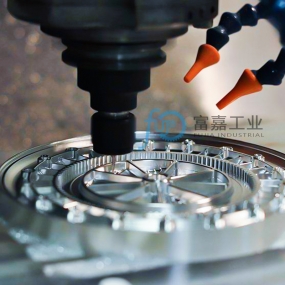

1. High precision: Sheet metal shell processing can ensure machining accuracy through molds and computer-aided design, achieving millimeter level precision requirements. Moreover, multiple corrections and adjustments can be made during the processing to ensure the accuracy of the product's size and shape.

2. Short production cycle: Compared with traditional mechanical processing methods, sheet metal shell processing saves cutting processes and only requires stamping, bending, welding and other processes to produce the required products, improving production efficiency and shortening the production cycle.

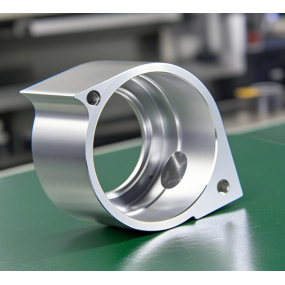

3. Wide applicability: Sheet metal shell processing can handle various materials, such as aluminum alloy, stainless steel, galvanized sheet, etc. And different combinations of materials can be selected according to the requirements of the product to achieve different performance requirements. In addition, sheet metal shell processing can also produce complex shaped products, such as circular, irregular, etc., with diverse shapes.

4. Low cost: Compared with other processing techniques, sheet metal shell processing does not require a lot of manual calculation and adjustment, only through molds and computer-aided design for processing, saving labor costs. Meanwhile, sheet metal shell processing can also improve material utilization, reduce waste, and further lower costs.

5. Environmental protection and sustainability: During the sheet metal shell processing, there is little waste generated, and the material utilization rate is high, reducing resource waste. Moreover, sheet metal materials can be recycled and reused, which has good sustainability.

Sheet metal shell processing has a wide range of applications, including:

1. In the field of communication equipment: Sheet metal casings are widely used in the production of casings for communication equipment such as base stations, routers, and switches, which can protect the equipment from external interference and provide a stable working environment.

2. In the field of electronic devices, such as computers, mobile phones, tablets, etc., the production of casings can protect electronic components and enhance product durability and safety through sheet metal casing processing.

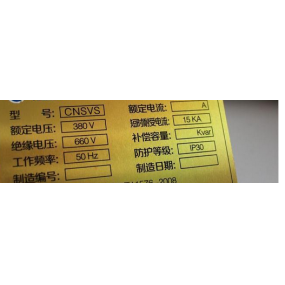

3. In the field of power equipment, the production of casings for power equipment such as transformers and capacitors can protect the equipment from external damage and prevent short circuits and leakage of electrical circuits through sheet metal casing processing.

4. In the field of automotive parts: Sheet metal shell processing can be used for the production of car doors, bodies, and other components, with high precision and durability, which can protect vehicles from external impacts and damage.

5. In the field of household appliances, such as refrigerators, washing machines, air conditioners, etc., the production of shells for household appliances can provide strength and durability through sheet metal shell processing, while increasing the aesthetic appearance of the product.

In summary, sheet metal shell processing has advantages such as high precision, short production cycle, wide applicability, low cost, and environmental sustainability. It is widely used in fields such as communication, electronics, power, automotive, and home appliances, and is an important processing technology.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque