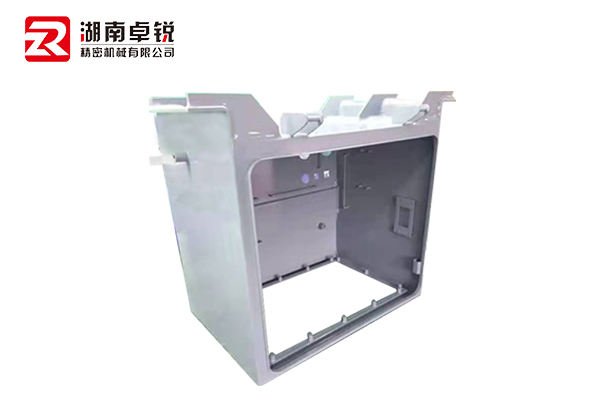

Chassis and cabinet Sheet Metal Processing is a customized processing service that can be customized according to customer requirements and needs. Sheet metal processing is a technology that uses metal sheets for processing, by cutting, bending, stamping, welding and other processes to process and shape metal sheets, and produce various shapes of chassis and cabinets. Due to the different application requirements of chassis cabinets in different fields and industries, customers often hope to customize chassis cabinets that meet their own needs. Can the sheet metal processing of chassis cabinets be customized according to customer requirements? Sheet metal processing company editor to answer.

Firstly, customized sheet metal processing services allow customers to design the shape and size of chassis and cabinets according to their own needs. Different customers have different space and installation requirements. Some customers may require large cabinets to accommodate multiple devices, while others may only need a small chassis to install one device. Sheet metal processing can produce chassis and cabinets that meet the size requirements and installation environment provided by customers.

Secondly, customized services for sheet metal processing can also design the internal structure of chassis cabinets according to customer functional requirements. Different devices have different functions and work requirements, so the internal structure of chassis cabinets needs to be designed according to the characteristics of the devices. For example, some servers require cooling equipment and space to maintain good heat dissipation performance, while some industrial control equipment needs to have dust-proof, waterproof, and anti-interference functions. Sheet metal processing can design suitable internal structures according to the equipment requirements provided by customers to ensure the normal operation of the equipment.

In addition, customized services for sheet metal processing can also design the external surface and material of the chassis and cabinet according to the customer's appearance requirements. Different customers have different requirements for the appearance of chassis cabinets. Some customers may focus more on the aesthetics and coordination of the appearance, while others may pay more attention to the durability and protection of the chassis cabinets. Sheet metal processing can choose appropriate external surface treatment methods and materials according to customer requirements, such as spraying, sandblasting, and electroplating, to meet customer appearance needs.

Customized sheet metal processing services can meet customers' personalized needs in terms of chassis and cabinets, enabling them to better adapt to different application environments and industry demands. Through customized sheet metal processing services, customers can design and produce a unique chassis cabinet according to their own needs, thereby improving equipment stability and work efficiency. Therefore, customized services for sheet metal processing are of great significance and value in the chassis and cabinet industry. By continuously improving our technological level and service quality, customized sheet metal processing services will provide customers with more and better choices, and promote the development of the chassis and cabinet industry.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque