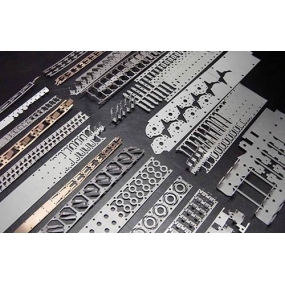

The rolling shearing method is a pair of disc shears with opposite rolling directions to cut the sheet. According to the disc equipment, it can be divided into three methods: straight equipment, oblique straight equipment and oblique equipment. Straight equipment is suitable for cutting the sheet into strips or cutting the square blank into a round blank in Shenyang Sheet Metal Processing. Oblique straight equipment is suitable for cutting round blanks or round inner holes, and oblique equipment is suitable for cutting blanks with arbitrary curves.

1. Oblique equipment clipboard material. Oblique equipment shearing is the most widely used in curve summary sheet shearing. Before the clipboard material, install the upper and lower hobs obliquely, and set the included angle of the upper and lower hobs to 25 degrees. Then adjust the speed and hob clearance according to the thickness of the sheet.

2. Straight equipment clipboard material. Use straight equipment clipboard material to install the straight center line of the upper and lower hob first, and the gap between the upper and lower cutting blades is generally 0.05-0 mm, or the upper and lower hobs are set to a slightly stacked state, so that the stacking height h is generally only 0.2-0 times the thickness of the shearing board.

2. Straight equipment clipboard material. Use straight equipment clipboard material to install the straight center line of the upper and lower hob first, and the gap between the upper and lower cutting blades is generally 0.05-0 mm, or the upper and lower hobs are set to a slightly stacked state, so that the stacking height h is generally only 0.2-0 times the thickness of the shearing board.

3. Oblique equipment shearing dimensional accuracy. When using the disc rolling shear curve to summarize, the radius of curvature of the blank has certain constraints, and its minimum radius of curvature is related to the diameter of the shearing blade and the thickness of the half material. When the disc rolling shears a straight strip, its minimum width error is also constrained.

The content of the article comes from the Internet. If you have any questions, please contact me to delete it!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque