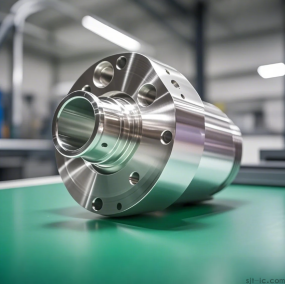

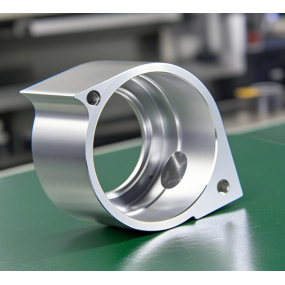

During the processing, stamping factories may cause various defects such as pits, bumps, cracks, scratches, wrinkles, and indentations on the surface of stamped parts due to various reasons. So it is necessary to adopt relevant methods to investigate. However, the detection method for the appearance defects of stamped parts can only intuitively reflect the existence of the defects, but cannot reflect the severity of the defects themselves.

At present, General Motors‘ GSQE (Global Surface Quality Assessment) system has been introduced in the appearance inspection of stamped parts, dividing the appearance of various parts of the vehicle into four areas: A, B, C, and D according to the degree of defect detection and the impact of defects on the overall appearance quality of the vehicle. A is a completely visible area, B is a generally visible area, C is a generally invisible area, and D is a completely invisible area. In addition, based on the degree of impact of appearance defects on the entire vehicle and the difficulty of being discovered, it can be classified into one, two, and three levels from low to high. The first level is a significant drawback, as it can be detected without the need for oiling or any light reflection; The second level is the disadvantage that needs to be identified through the principle of light reflection. The investigation method is as follows: stand at a distance of 23m from the investigation point and identify from two or more different directions perpendicular to the investigation point 3045. The third level is a relatively minor level of disadvantage that may not be visible when exposed to strong light. It is necessary to investigate carefully and be able to view it up close from one direction or viewpoint.

Based on the orientation and difficulty level of the defects, the appearance defects of stamped parts have different deduction values. The inspection personnel of stamping processing plants can judge the severity of the defects based on the deduction values and formulate corresponding preventive measures, which can effectively control the appearance quality of stamped parts.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque