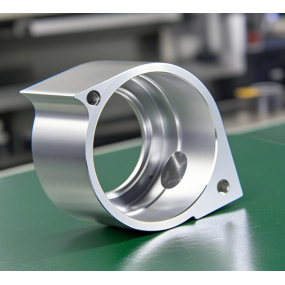

During the production of stamped parts, stamping factories may experience damage due to factors such as the service life of hardware molds, mold structure planning, selection of mold steel, heat treatment, surface treatment, mechanical processing and grinding, wire cutting technology, stamping equipment and processes, mold smoothness, and maintenance and repair level.

How to avoid damage to stamped parts during the production process:

1. Revamp stamping equipment to improve production safety and reliability. At present, there are many unsafe factors in the operating system and electrical control system of many outdated stamping equipment. If we continue to use them, we will carry out corresponding technical transformations. Stamping equipment manufacturers should improve product design to ensure the safety and reliability of stamping equipment; Install protective equipment. Due to the small production volume, it is necessary to install safety protection equipment in stamping operations that cannot be automated or use safety stamping tools to avoid injury accidents caused by operational errors. Various protective devices have their own unique characteristics and application scope, and improper use can still lead to injury accidents. Therefore, it is necessary to clarify the effectiveness of various protective equipment in order to ensure correct use and safe operation;

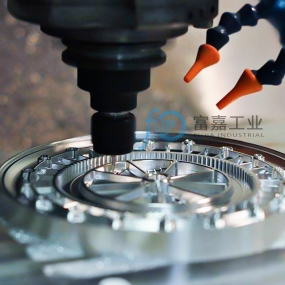

3. Transform the process, molds, and operation methods to complete manual mold work. For large-scale production operations, mechanization and automation can be achieved by starting with changing processes and molds. For example, stamping processing plants can choose automated, multi station stamping machinery equipment, use multi cutting tools and mechanized production equipment, and adopt combined process methods such as continuous molds and composite molds. All of these not only ensure the safety of stamping operations, but also greatly improve production power.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque