Five axis CNC Machining provides unlimited possibilities for the size and shape of parts that can be effectively machined. The term ‘five axes‘ refers to the number of directions in which the cutting tool can move. On a five axis CNC machining center, the tool moves along the X, Y, and Z linear axes and rotates along the A and B axes to approach the workpiece from any direction. In other words, you can handle the five sides of the part in one setup. The advantages and uses of five axis machining are diverse.

Processing cluttered shapes in a single setting to improve productivity

Prepare with fewer fixtures to save time and money

Improve throughput and cash flow while reducing delivery time

Higher part accuracy, as the workpiece will not move across multiple workstations

Shorter cutting tools can be used to achieve higher cutting speeds and less tool vibration

Achieve outstanding surface finish and overall better part quality

Five axis CNC machining application

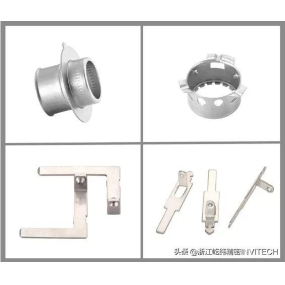

Five axis CNC machining can be used for many purposes, such as precision milling of aluminum 7075 for aircraft parts. We are a professional manufacturer of 7075 aluminum aircraft parts with five axis CNC precision machining and milling, primarily used in the aerospace and aircraft industries. We can process various chaotic shaped parts through five axis CNC machining and five axis milling, saving time and money with fewer fixture preparations and higher part accuracy.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque