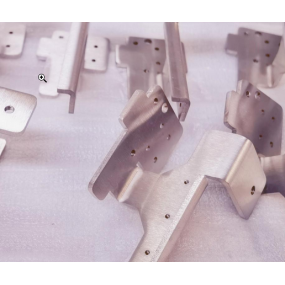

1. Efficient and stable processing speed

The high or low processing speed of the five axis CNC connector parts is worth commenting on, and it is also an indicator that customers will compare carefully before purchasing. It should be noted that some customers are temporarily interested and have urgent requirements for processing time. The five axis machining of connector parts must adhere to an efficient and stable speed in order to complete various processing tasks in an orderly manner and not delay the subsequent operations of customers.

2. Having strict processing procedures

The five axis CNC Machining process for connector parts is relatively strict because the structure of the parts in the machining stage is unique. Once the machining process becomes chaotic, it is difficult to produce parts that meet the requirements. Connector component five axis CNC manufacturers who are well aware of this point will emphasize the importance of the process and urge each processing personnel to strictly adhere to their own behavior standards.

3. The errors generated are relatively small

Five axis CNC connectors with reasonable prices often attract customer attention, but not all similar organizations can achieve high customer satisfaction. Only those with small errors will be included in the selection category. After all, the five axis processed products of connector parts will be installed in precision equipment, and parts with large errors cannot be used at all.

The characteristics that the five axis CNC machining of connector parts should have happen to coincide with the description above. We must have never thought about this issue carefully, but only asked our old friends and partners before making a purchase. It is recommended to identify the experienced CNC axis machining organization for connector parts and understand the advice given by professionals in order to correct the selection direction.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque