In recent years, the rapid development of CNC Machining technology in China has provided strong technical support for the industrialization of UAVs. Numerically controlled machining manufacturers have joined in. Domestic Dajiang, Jifei and Yihang are even more amazing. Some Internet enterprises also value the unprecedented market of UAVs, such as Jingdong in the express industry, Google in search and other large enterprises.

Experts engaged in hardware technology research have pointed out that the application of intelligent mechanical parts processing aircraft has developed from the military field to the civilian field, and its application in the consumer and industrial fields is unprecedentedly broad, such as Xinxing‘s express logistics, leisure and entertainment, aerial photography, photography, film and television shooting, fire extinguishing, traffic management, agricultural planting, land surveying and search and rescue, etc. Undoubtedly, the impact of drones on people‘s production and life has become increasingly close;

There are also aluminum alloy processing experts who remind us that 2015 is the "first year" for China to officially enter the development of intelligent mechanical parts processing aircraft. With the continuous acceleration of the scale of the drone field, the drone industry, as one of the new engines of intelligent processing in China, has shown an unstoppable and explosive development trend. Currently, many precision machining manufacturers in Shenzhen have achieved significant results in technology research and development, product categories, market size, and application fields of intelligent processing;

There are also aluminum alloy processing experts who remind us that 2015 is the "first year" for China to officially enter the development of intelligent mechanical parts processing aircraft. With the continuous acceleration of the scale of the drone field, the drone industry, as one of the new engines of intelligent processing in China, has shown an unstoppable and explosive development trend. Currently, many precision machining manufacturers in Shenzhen have achieved significant results in technology research and development, product categories, market size, and application fields of intelligent processing;

According to the information network of relevant enterprises, there are over 4000 enterprises in China‘s intelligent mechanical processing parts and aircraft industry chain, of which more than half have entered and emerged in the past five years. In addition, the market entities composed of higher education institutions and research institutions in the aerospace field have injected a continuous stream of power into the development of such aircraft. They are leading in core technology and patents, and have spawned innovative hardware mechanical processing technology through hardcore research and development. Blind has withdrawn from thousands of mature unmanned aerial vehicle products.

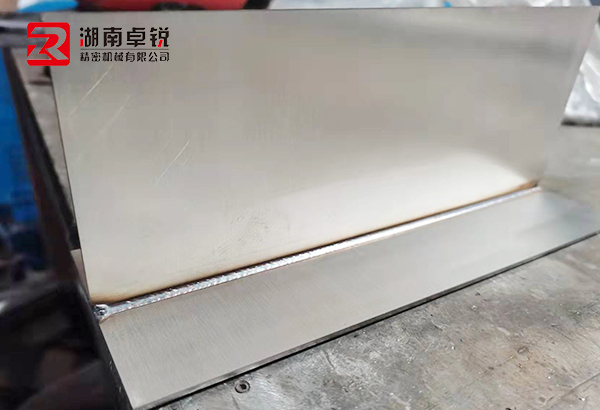

Shenzhen EMAR Precision Technology Co., Ltd. focuses on the customization and mass production of high-precision unmanned aerial vehicle components. Currently, our company is equipped with more than 100 high-precision CNC machining machines, which have the advantages of high precision and efficiency in unmanned aerial vehicle precision components, unmanned aerial vehicle axis cores, and unmanned aerial vehicle assembly processing. After years of development, the company has passed the national high-tech enterprise and Shenzhen high-tech enterprise audits, successfully passed ISO9001, IATF16949 quality management certifications, and strictly implemented relevant standards.

Shenzhen EMAR Precision Technology Co., Ltd. focuses on the customization and mass production of high-precision unmanned aerial vehicle components. Currently, our company is equipped with more than 100 high-precision CNC machining machines, which have the advantages of high precision and efficiency in unmanned aerial vehicle precision components, unmanned aerial vehicle axis cores, and unmanned aerial vehicle assembly processing. After years of development, the company has passed the national high-tech enterprise and Shenzhen high-tech enterprise audits, successfully passed ISO9001, IATF16949 quality management certifications, and strictly implemented relevant standards.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole