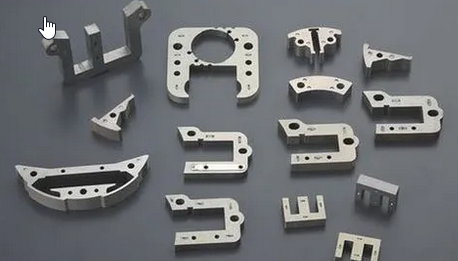

The Metal Stamping parts produced by stamping factories are characterized by relatively small material thickness, large structural dimensions, complex shapes, high requirements for dimensional accuracy and appearance quality compared to ordinary thin sheet stretching parts; When forming automotive metal stamping parts, the deformation of various parts on the blank is complex and significant, and the stress is uneven, making it prone to surface defects such as rebound, wrinkling, cracking, and stamping lines. Let me briefly explain the impact line:

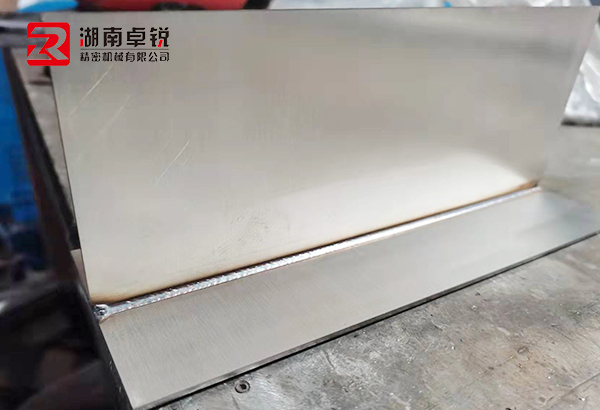

The impact line is caused by the displacement of the contact point between the material and the punch during the forming process of metal stamping parts, as well as the different resistance during material forming. The bottom sheet metal moves through the top of the punch, and its external motion static conflict is transformed into a dynamic conflict resulting in the formation of impact traces; The reason for the occurrence of stamping lines is generally due to differences in resistance during the sheet metal forming process, or significant deformation of the bottom surface of the parts. According to the deformation trend law of metal stamping parts, it can be known that the distribution of tensile deformation along the periphery of the blank in the deformation zone of metal stamping parts is uneven. The area of the straight edge of the blank is smaller than that of the rounded corner, so the deformation force required for compression deformation at the straight edge is smaller than that at the rounded corner.

Due to the unevenness of the convex mold touching the sheet metal, a mode change occurs during the movement of the bottom sheet metal, from the initial bulging to the impact line that occurs during the deep drawing process. The surface forming is a continuous whole, and the displacement of the impact line increases continuously during the continuous movement of the sheet metal. The maximum displacement of the impact line occurs at the highest point of the convex mold upward movement, which is when the forming is completed.

The problem of impact lines is becoming increasingly apparent and has become a disadvantage of linear appearance in the processing of metal stamping parts. This disadvantage brings many difficulties to mold design and repair for the production power of metal stamping parts.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole