The processing steps for sheet metal parts are: product pre testing, product processing trial production, and mass production of products. During the product processing and trial production steps, timely communication and contact with customers should be made to obtain corresponding processing evaluations before proceeding with mass production of the product.

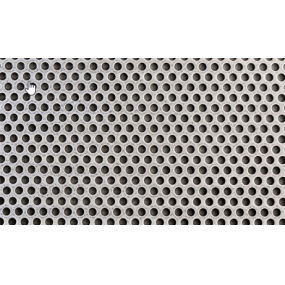

Laser drilling technology is the earliest practical laser technology in laser material processing technology. Laser drilling in sheet metal workshops generally uses pulsed laser, which has high energy density and short time. It can process small holes of 1 μ m, especially suitable for processing small holes with certain angles and thin materials. It is also suitable for processing deep small holes and micro holes on parts with high strength, hardness or brittle soft materials.

Laser can achieve drilling and processing of burner components for gas turbines, and the drilling effect can be three-dimensional, with a quantity of up to thousands. The materials that can be drilled include stainless steel, nickel chromium iron alloy, and Hastelloy based alloy. Laser drilling technology is not affected by the mechanical properties of materials and is relatively easy to achieve automation.

With the development of laser drilling technology, laser cutting machines have achieved automated operation, and their application in the sheet metal industry has changed the traditional processing methods of sheet metal technology, realizing unmanned operation, greatly improving production efficiency, realizing fully automatic operation throughout the process, driving the development of sheet metal economy, and improving the drilling effect to a higher level. The processing effect is remarkable.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque