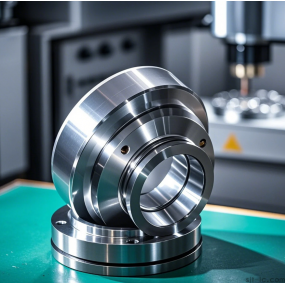

Optical communication component processing refers to the process of manufacturing and processing various parts and components used in optical communication systems. These parts and components include fiber optic cables, optical cables, fiber optic connectors, fiber optic adapters, fiber optic attenuators, fiber optic couplers, etc. Quality standards are crucial in the manufacturing process of optical communication components. The following are some common quality standard requirements:  Dimensional accuracy: The dimensional accuracy of optical communication parts must be strictly controlled to ensure that the parts can be assembled correctly together. This usually requires the use of high-precision measuring equipment for verification. Surface quality: The surface quality of optical communication components has a significant impact on the transmission quality of optical signals. Therefore, the surface of the parts must be flat, smooth, and free of defects such as scratches and dents. Optical performance: The optical performance of optical communication components is crucial. For example, the refractive index, attenuation and other parameters of optical fibers must meet the design requirements to ensure efficient transmission of optical signals in the fiber. Environmental adaptability: Optical communication components must be able to operate normally under various environmental conditions, including temperature, humidity, mechanical vibration, etc. Therefore, the parts must undergo strict environmental adaptability testing. Reliability: Optical communication components must have high reliability to ensure long-term stable operation. This usually requires long-term aging testing and reliability evaluation. Safety: Optical communication components must comply with relevant safety standards to ensure that they do not pose a threat to personnel and the environment during use.

Dimensional accuracy: The dimensional accuracy of optical communication parts must be strictly controlled to ensure that the parts can be assembled correctly together. This usually requires the use of high-precision measuring equipment for verification. Surface quality: The surface quality of optical communication components has a significant impact on the transmission quality of optical signals. Therefore, the surface of the parts must be flat, smooth, and free of defects such as scratches and dents. Optical performance: The optical performance of optical communication components is crucial. For example, the refractive index, attenuation and other parameters of optical fibers must meet the design requirements to ensure efficient transmission of optical signals in the fiber. Environmental adaptability: Optical communication components must be able to operate normally under various environmental conditions, including temperature, humidity, mechanical vibration, etc. Therefore, the parts must undergo strict environmental adaptability testing. Reliability: Optical communication components must have high reliability to ensure long-term stable operation. This usually requires long-term aging testing and reliability evaluation. Safety: Optical communication components must comply with relevant safety standards to ensure that they do not pose a threat to personnel and the environment during use.

Hello! Welcome to EMAR's website!

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque