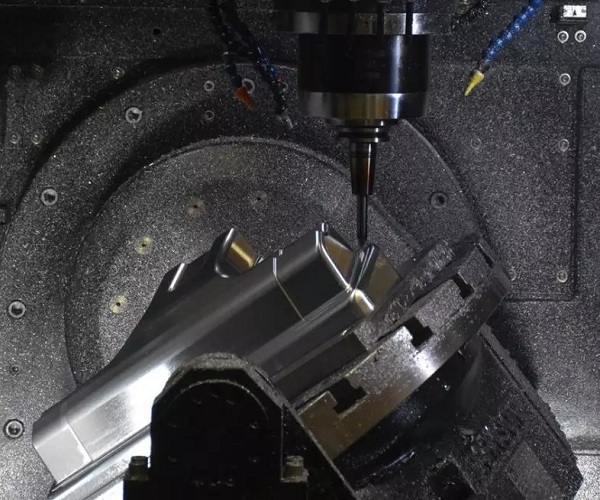

Undoubtedly, five axis machining technology is becoming increasingly widespread in the field of mechanical processing, and has even become closely related to people‘s daily lives. However, the cutting tools we see in machining manufacturers are still relatively simple flat bottomed cutters and ball end mills. This difference was not significant more than a decade ago, and everyone thought it was natural. In fact, can the shape of five axis machining tools only be so simple? The answer is negative. Five axis machining centers can perform complex linkage operations and support the use of more flexible machining routes to improve machining efficiency. Cutting tool manufacturers have gradually withdrawn from a series of large arc new milling tools. By using various convenient and reliable machining strategies more reasonably, they can fully tap into the machining potential of five axis machine tools;

1 Large arc milling cutters and superstring precision machining technology

1 Large arc milling cutters and superstring precision machining technology

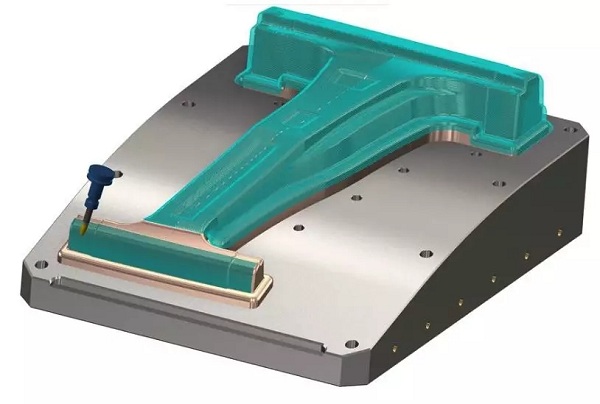

The large arc milling cutter, also known as the drum milling cutter or parabolic milling cutter in the industry, can perform surface machining on various complex parts, especially in the mold industry. Reasonable machining route programming is the key to effectively using large arc cutting tools. In machining route planning, it is necessary to base on the geometric shape of the cutting edge of the tool, so that the special shaped cutting edge in the tool can contact the workpiece surface at a suitable angle during the cutting process;

In order to meet this requirement, tool manufacturers have collaborated with CAM software developers to develop a programming tool that can implement this type of tool design concept. The future of CNC precision machining technology is quietly approaching. Mastercam‘s superstring precision machining technology is based on the precise contour of circular arc cutting tools in the machining process of workpieces with relatively high surface quality. By controlling the cutting path of the tool to achieve appropriate angles and precise fitting of the workpiece contour shape, the machining cycle time can be greatly reduced under the premise of ensuring surface quality. Large circular arc cutting tools basically need to be used in conjunction with five axis CNC machine tools, especially in the field of mold processing, to maintain the required angle cutting. Mastercam‘s superstring precision machining technology can organically combine the shape of the tool with the complex motion performance of the five axis machine tool, greatly improving the efficiency of precision machining;

2 How do you view these new types of milling cutters

What role is CAM software playing? When the concept of large arc cutting tools was first proposed, CNCSoftware began to engage in in-depth technical exchanges with tool manufacturers for collaborative research and development. CNC Software engineer Jesse Trinque even participated deeply in the development of Mastercam‘s programming solution for large arc cutting tools. What is his opinion on this new type of milling cutter? What is the role of CAM software in this new cutting concept?

In the past, CAM software did not actually model cutting tools accurately, "he said.

In the past, CAM software did not actually model cutting tools accurately, "he said.

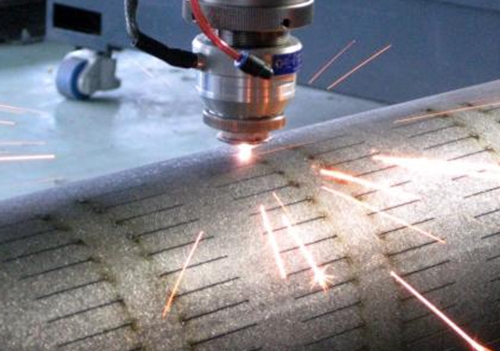

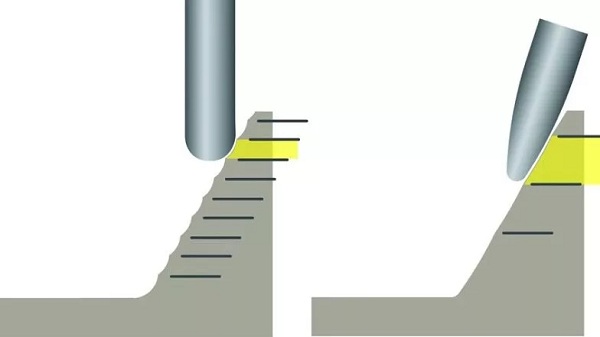

The best report on the investment in new technology research and development is the significant improvement in precision machining efficiency. The special curvature cutting edge used by large arc cutting tools is used for precision milling along the surface contour. When using ball cutters for precision machining, the curvature of the cutting point is first compared to the radius of the tool. In contrast, large arc cutting tools such as elliptical milling cutters and cylindrical milling cutters can use very large curvature cutting edges on small radius tool bodies for machining;

CAM software is crucial for using circular arc tools, and maintaining the required precise meshing angle requires customized tool paths for each different type of circular arc segment tool. The advantage of a ball cutter is that it does not need to consider the meshing angle between the tool tip shape and the workpiece surface shape when using it. Regardless of which angle is used, the shape of the tool tip contact point is always circular. Jesse said that the disadvantage of using a ball cutter for precision machining is that the machining cycle time will be relatively long, and the ball cutter requires a relatively small step to ensure the surface quality of precision machining. When the surface being machined is relatively large, the machining time will become very long. Using a large circular arc cutter can achieve the same machining quality with a larger one. In this way, the cycle time can be significantly compressed. However, when using a large arc cutting tool, it is necessary to keep the cutting edge in contact with the workpiece at an appropriate angle so that the contour of the large radius cutting edge can play a role;

CAM software is crucial for using circular arc tools, and maintaining the required precise meshing angle requires customized tool paths for each different type of circular arc segment tool. The advantage of a ball cutter is that it does not need to consider the meshing angle between the tool tip shape and the workpiece surface shape when using it. Regardless of which angle is used, the shape of the tool tip contact point is always circular. Jesse said that the disadvantage of using a ball cutter for precision machining is that the machining cycle time will be relatively long, and the ball cutter requires a relatively small step to ensure the surface quality of precision machining. When the surface being machined is relatively large, the machining time will become very long. Using a large circular arc cutter can achieve the same machining quality with a larger one. In this way, the cycle time can be significantly compressed. However, when using a large arc cutting tool, it is necessary to keep the cutting edge in contact with the workpiece at an appropriate angle so that the contour of the large radius cutting edge can play a role;

By using a much larger tip arc than a ball cutter, large arc cutting tools can perform precision machining more interestingly. The taper type cutting tool here is an extreme case, where its cutting edge looks basically straight. This type of tool requires very precise meshing angles for precision machining. What kind of contact angle is needed for precision machining? Jesse said that elliptical cutting tools are limited to a contact angle of only 15 degrees within the effective contact area, and the taper form is even more limited. The variation of their meshing angle cannot exceed 0.1 degrees. In contrast, the angle of a ball tool within its range of motion is actually infinite. This is why ball tools can be used on almost all machining centers, but large arc cutting tools are mainly used on five axis CNC machines.

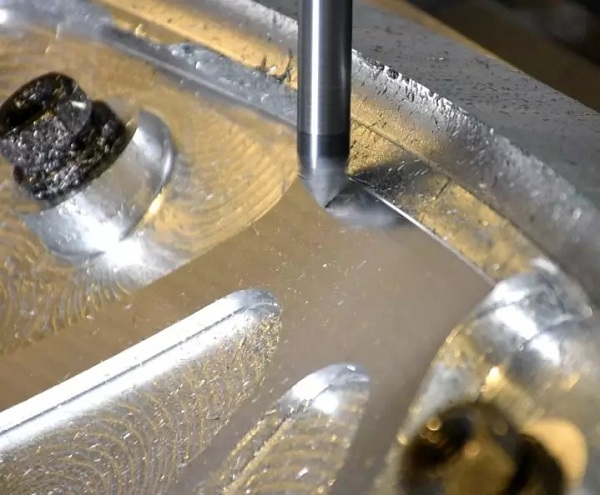

He also said that circular arc milling cutters are suitable for milling open large curved surface features on workpieces, such as how to use lens type cutting tools to precision mill the step area of the mold cavity, and how to use tapered or elliptical cutting tools to precision machine the sidewall of the mold core. Generally speaking, using a ball cutter to process these areas may take several hours, while using a combination strategy of centralized large circular arc milling cutters can compress the processing time to within an hour. Compared to its ball cutter, how does the large arc cutter save cycle time? By utilizing a larger blade tip curvature, it is possible to achieve the same residual ridge height with a larger step increment. This approach not only improves productivity, but also results in components with better surface smoothness;

He also said that circular arc milling cutters are suitable for milling open large curved surface features on workpieces, such as how to use lens type cutting tools to precision mill the step area of the mold cavity, and how to use tapered or elliptical cutting tools to precision machine the sidewall of the mold core. Generally speaking, using a ball cutter to process these areas may take several hours, while using a combination strategy of centralized large circular arc milling cutters can compress the processing time to within an hour. Compared to its ball cutter, how does the large arc cutter save cycle time? By utilizing a larger blade tip curvature, it is possible to achieve the same residual ridge height with a larger step increment. This approach not only improves productivity, but also results in components with better surface smoothness;

It is said that superstring precision machining can not only be used for mold processing, but also for aerospace parts and medical implants with large surface features. Especially for aerospace and medical equipment parts, many are already being processed using five axis CNC machines. We recently assisted a company in processing titanium alloy knee components, "he said. This part is processed using a five axis machine tool, and the original precision machining cycle time was 70 minutes. We used large arc cutting tools combined with Mastercam‘s superstring precision machining technology to shorten the precision machining cycle time to 10 minutes, and its surface quality is even better than before

The ball cutter is still very important. Sometimes, there may be some small gap features in complex parts, and only the ball cutter can penetrate into the gap at a suitable angle for precision machining. Indeed, Mr. Jesse said that this is a reality that users need to recognize when accepting the precision machining concept of new tools and cores;

Companies that have heard of superstring precision machining and large arc cutting tools often hope to apply them to all machining, but such machining methods have their limitations: they are not suitable for rough machining, and each shape of tool has its own advantages and limitations. Understanding these different shapes of tools and the workpiece characteristics they are suitable for can help CNC engineers expand their programming ideas, process different features on the workpiece in a more flexible way, and improve the overall precision machining efficiency. In the past, it was possible to slowly precision machine a complex cavity with only a ball cutter during programming, "he said. By understanding the precision machining technology of superstring, different shapes of cutting tools and different cutting paths can be selected according to the characteristics of different areas in the cavity during programming, in order to complete precision machining with higher efficiency and lower cost

Jesse said that this is the way future CNC engineers need to think. In his opinion, using tools with more complex cutting edge shapes is the future of precision machining. The continuous evolution of tools can combine the complex cutting paths that CAM software can achieve with the complex CNC machine movements that five axis machining centers can achieve, which is a very important factor in improving precision machining efficiency. He also said that many tool manufacturers are also introducing more efficient and different shaped tools. Mastercam no longer defines tools as simple shapes, but as an indispensable and important component of efficient precision machining;

Jesse said that this is the way future CNC engineers need to think. In his opinion, using tools with more complex cutting edge shapes is the future of precision machining. The continuous evolution of tools can combine the complex cutting paths that CAM software can achieve with the complex CNC machine movements that five axis machining centers can achieve, which is a very important factor in improving precision machining efficiency. He also said that many tool manufacturers are also introducing more efficient and different shaped tools. Mastercam no longer defines tools as simple shapes, but as an indispensable and important component of efficient precision machining;

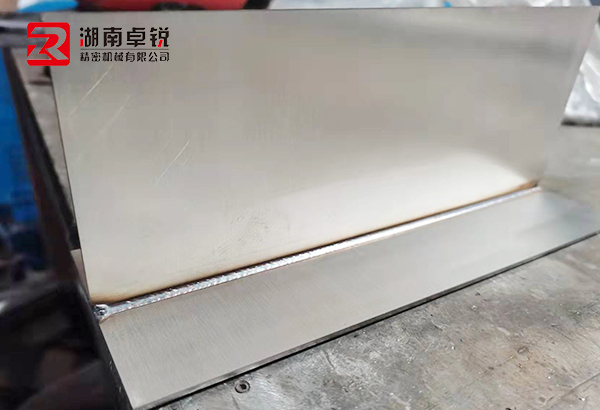

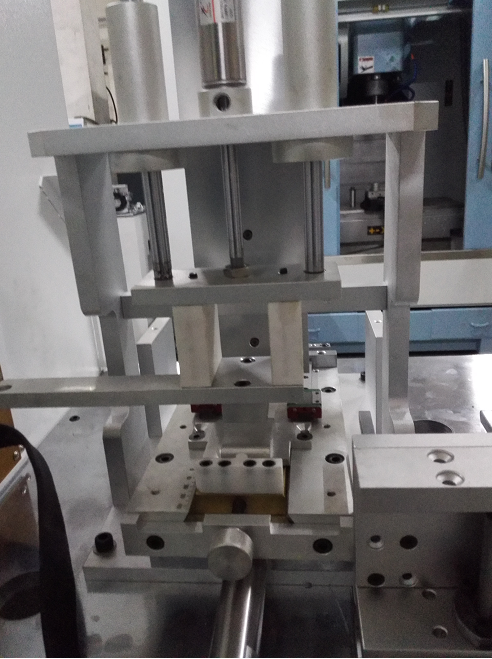

Shenzhen EMAR Precision Technology focuses on the external processing of high-precision CNC machine tools. Over the years, it has continuously updated and optimized its production processes and introduced high-precision CNC Machining machines. Currently, EMAR Precision Technology provides CNC core walking machines, CNC cutting machines, turning and milling composite machines, and CNC machining centers for external processing services. Especially in the fields of medical parts, automotive parts, aviation parts, as well as communication and optical parts processing, it has accumulated more than 20 years of experience and can easily handle precision machining tasks of various materials and complex structural components.

Shenzhen EMAR Precision Technology focuses on the external processing of high-precision CNC machine tools. Over the years, it has continuously updated and optimized its production processes and introduced high-precision CNC Machining machines. Currently, EMAR Precision Technology provides CNC core walking machines, CNC cutting machines, turning and milling composite machines, and CNC machining centers for external processing services. Especially in the fields of medical parts, automotive parts, aviation parts, as well as communication and optical parts processing, it has accumulated more than 20 years of experience and can easily handle precision machining tasks of various materials and complex structural components.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole