What is the importance of sheet metal processing? Generally speaking, sheet metal processing factories have equipment including shearing machines, CNC punching machines, laser plasma, water jet cutting machines, laminating machines, bending machines, and various auxiliary equipment such as unwinding machines, leveling machines, deburring machines, spot welding machines, etc.

Sheet metal processing is called sheet metal processing, and the primary processes are cutting, bending, shaping, welding, etc. The surface treatment of sheet metal parts is a very important part of the sheet metal processing process, as it has the effects of preventing parts from rusting and beautifying the appearance of the product.

Sheet metal processing technology, issues to be noted in the design of sheet metal chassis processing. The surface pre-treatment of sheet metal parts is primarily effective in removing oil stains, oxide scales, rust, etc. It prepares for surface post-treatment, and then the treatment mainly includes spraying (baking) paint, spraying plastic, and plating anti rust layers.

Under the requirements of satisfying the product‘s functionality, appearance, etc., the planning of sheet metal should ensure that the stamping process, stamping tool production, sheet Metal Stamping quality are high, standardized and stable, etc. It can be seen that production equipment, sheet metal processing, and the processing ability of the master all affect the quality of sheet metal processing.

Many people want to know the production process of sheet metal processing, and skilled sheet metal engineers will provide you with detailed explanations. At the beginning, sheet metal processing designers will choose different cutting methods based on the unfolded drawings and large quantities, including laser, CNC machine tools, shearing, grinding tools, etc. Then, they will make corresponding adjustments according to the engineering drawings.

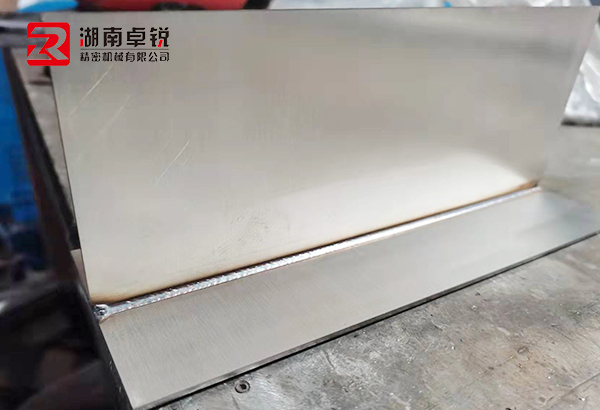

However, for the longer production and processing time of small steel parts, placing an operating table next to the CNC machine and laser is beneficial for placing thick plates on the equipment for production and processing, reducing the labor required for lifting the plates. Some usable edge materials are placed in special areas to provide raw materials for the specimens during sheet metal bending.

After the sheet metal processing of steel parts, the edges, burrs, and contacts need to be repaired. At the CNC blade contact points, a flat filing knife is used for repair. For steel parts with large burrs, an electric polishing machine is used for repair. At the small inner hole contact points, corresponding small filing knives are used for repair to ensure a beautiful and elegant appearance.

In addition, the refurbishment of the exterior design also ensures precise positioning during sheet metal bending, allowing the steel parts to rest together on the CNC bending machine during sheet metal bending, ensuring consistency in product specifications for the same batch. After the material is dropped, it enters the next process, and different steel parts are processed according to the production and processing rules into the corresponding process flow.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole