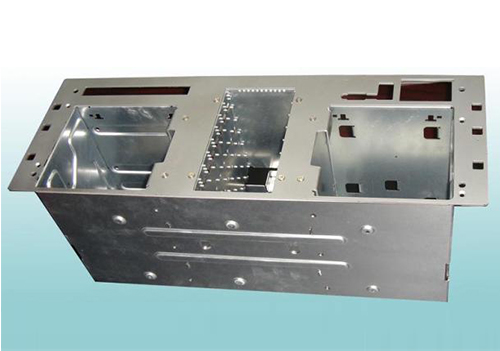

Common process flow of Sheet Metal Processing

1 The selection of materials for sheet metal processing generally includes cold-rolled sheet metal (SPCC), hot-rolled sheet metal (SHCC), galvanized sheet metal (SECC, SGCC), copper (CU), brass, purple copper, beryllium copper, aluminum plates (6061, 6063, hard aluminum, etc.), aluminum profiles, stainless steel (mirror, brushed surface, matte surface). The selection of materials varies depending on the product‘s function, and generally needs to be considered based on its purpose and cost.

1. Cold rolled SPCC sheet is mainly used for electroplating and baking paint parts, with low cost, easy molding, and a material thickness of 3.2mm.

2. Hot rolled plate SHCC, material T3.0mm, also uses electroplating and baking paint parts, with low cost but difficult to form, mainly using flat parts.

3. Galvanized sheet SECC SGCC. SECC electrolytic plates are divided into N material and P material. N material is mainly not surface treated and has a high cost, while P material is used for spraying.

4. Copper; Mainly using conductive materials, the surface treatment is nickel plating, chromium plating, or no treatment, which is costly.

5. Aluminum plate; Generally, surface chromate (J11-A) is used for oxidation (conductive oxidation, chemical oxidation), which is costly. Silver plating and nickel plating are available.

6. Aluminum profiles; Materials with complex cross-sectional structures are widely used in various plug-in boxes. Surface treatment is the same as aluminum plate.

7. Stainless steel; Mainly used without any surface treatment, high cost.

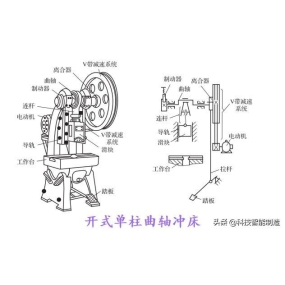

2 To review the drawings and write the process flow of the parts, it is necessary to first understand the various technical requirements of the part drawings; The review of drawings is the most important step in writing the process flow of parts.

1. Check if the drawing is complete.

2. The relationship between the drawing and view, whether the annotations are clear and complete, and the units of dimension annotations.

3. Assembly relationship, key dimensions required for assembly.

4. Differences between old and new layouts.

5. Translation of foreign language images.

6. Conversion of table codes.

7. Feedback and handling of graphic issues.

8. Materials

9. Quality requirements and process requirements

10. The official release of drawings must be stamped with a quality control seal.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque