Sheet Metal Processing, as an important metal processing technology, is widely used in various industrial fields. It involves a series of operations such as cutting, bending, welding, and polishing metal sheets, and ZUI shapes them into the desired shape and structure. Sheet metal processing not only requires high processing accuracy, but also requires smooth and aesthetically pleasing surfaces, thus occupying a pivotal position in the manufacturing industry. Today, let‘s learn more about the process, application, and trends of sheet metal processing together with the sheet metal processing manufacturer editor.

1. Basic process of sheet metal processing

1. Basic process of sheet metal processing

The basic process of sheet metal processing includes multiple stages such as design, material selection, cutting, bending, welding, and surface treatment.

Design: Based on the functional and appearance requirements of the product, use CAD and other design software to draw accurate sheet metal structure diagrams.

Material selection: Choose suitable metal materials such as stainless steel, aluminum alloy, copper, etc. based on the purpose and performance requirements of the product.

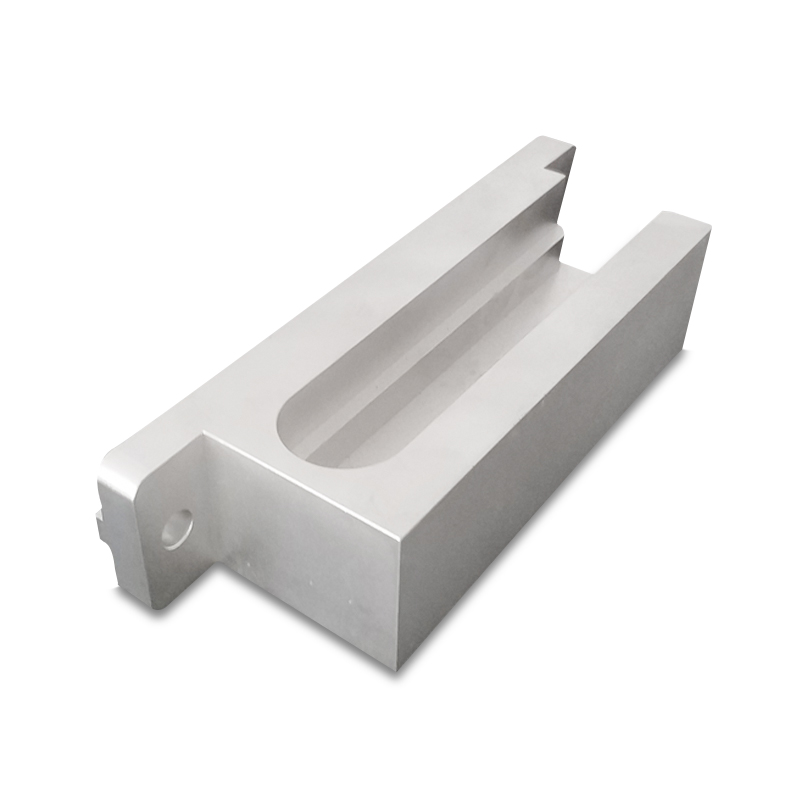

Cutting: Use laser cutting machines, shearing machines, and other equipment to cut metal sheets into the desired shape according to the design drawings.

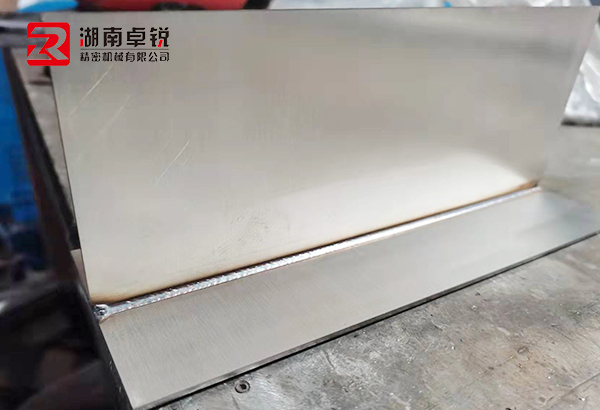

Bending: The cut sheet is bent by a bending machine to form the desired three-dimensional structure.

Welding: Welding the components that need to be connected, commonly used welding methods include arc welding, argon arc welding, etc.

Surface treatment: Surface treatment of processed sheet metal parts, such as spraying, oxidation, electroplating, etc., to improve their corrosion resistance and aesthetics.

2. Application areas of sheet metal processing

Sheet metal processing technology is widely used in various fields, such as machinery, electronics, communication, medical, aerospace, etc.

In the field of machinery, sheet metal processing can be used to manufacture various mechanical shells and structural components, such as machine tool casings, gearbox housings, etc.

In the electronics industry, sheet metal processing is commonly used to manufacture components such as casings and brackets for electronic devices, such as computer cases and mobile phone casings.

In the field of communication, many components in communication equipment need to be completed through sheet metal processing, such as base station antenna brackets, communication cabinets, etc.

In the medical field, sheet metal processing also plays an important role in the manufacturing of medical devices, such as operating tables, examination tables, and other medical equipment.

Aerospace field: Due to the high precision and reliability of sheet metal processing, it has also been widely used in the aerospace field, such as aircraft wings, rocket launchers, etc.

3. Development trend of sheet metal processing

With the advancement of technology and the development of manufacturing industry, sheet metal processing technology is also constantly developing and innovating. In the future, sheet metal processing will develop in the following directions:

High precision machining: With the continuous improvement of precision manufacturing technology, sheet metal machining will achieve higher machining accuracy and more complex structures.

Green and environmentally friendly: In the production process, more attention will be paid to environmental protection and energy conservation, promoting the sustainable development of the sheet metal processing industry.

Intelligent production: By introducing intelligent equipment and systems, automation and intelligent production of sheet metal processing can be achieved, improving production efficiency and product quality.

Application of new materials: With the continuous development of new material technology, new metal materials will gradually be applied in the field of sheet metal processing, bringing more possibilities to products.

Sheet metal processing, as an important metal processing technology, plays an irreplaceable role in the manufacturing industry. In the future, with the continuous advancement of technology and the expansion of application fields, sheet metal processing will usher in a broader development space and a better development prospect.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole