Today, the chassis and cabinet Sheet Metal Processing editor will take you to understand the industry standards for sheet metal processing.

The industry standards for sheet metal processing mainly include the following aspects:

Accuracy level and dimensional tolerance: The accuracy level of sheet metal processing is usually divided into A level, B level, and C. These levels correspond to the JISB2201 standard. The dimensional tolerance shall comply with the provisions of GB/T9124-1988 "Shape and Position Tolerance".

Accuracy level and dimensional tolerance: The accuracy level of sheet metal processing is usually divided into A level, B level, and C. These levels correspond to the JISB2201 standard. The dimensional tolerance shall comply with the provisions of GB/T9124-1988 "Shape and Position Tolerance".

Surface roughness: The surface roughness of various types of sheet metal should be executed according to the provisions in Table 1.

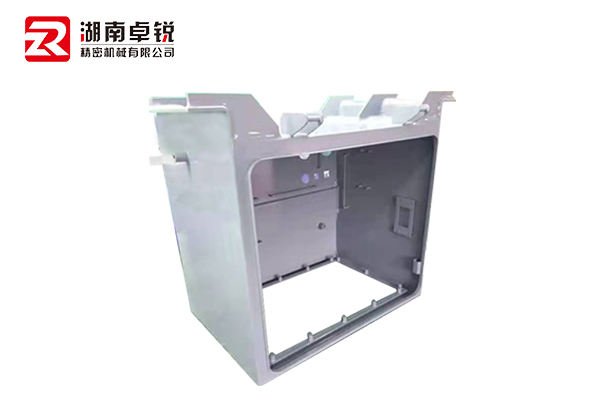

Bending degree: The bending degree of metal sheet shall not exceed 0.1% of the corresponding external dimensions of the parts.

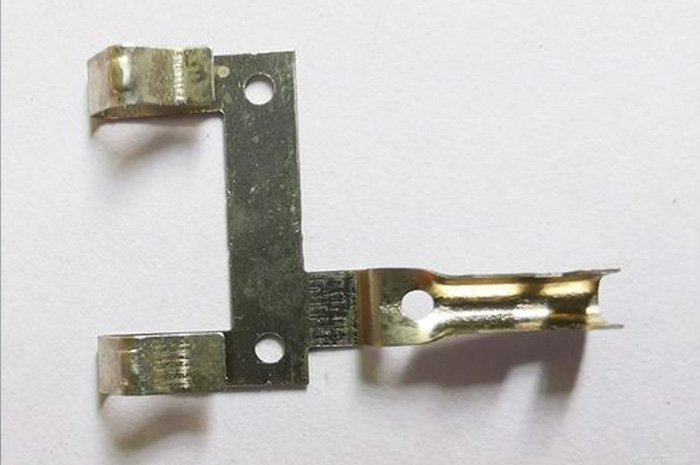

Bending requirements: When bending metal sheets, the distance between each point on the outer edge of the opening should not exceed 0.3d; When bending without welding, the distance between the inner edge of the opening and the inner hole wall should not exceed 0.5d.

Groove treatment: When the thickness of the metal sheet is less than 6mm or greater than 25mm, groove treatment should be carried out.

Straightness and perpendicularity: The allowable deviations for straightness and perpendicularity of asymmetric thin plates with a thickness between 10-15mm and no reinforcing ribs are 0.2d and 1.0d, respectively; When the symmetry of rectangular plates with a thickness between 16 and 30mm is poor, it is advisable to use single-sided drawing method for manufacturing.

Test method for non-metallic materials: The tensile test method for non-metallic materials should comply with the relevant provisions of GB/T1392-1993 "Tensile Test Method for Metallic Materials at Room Temperature".

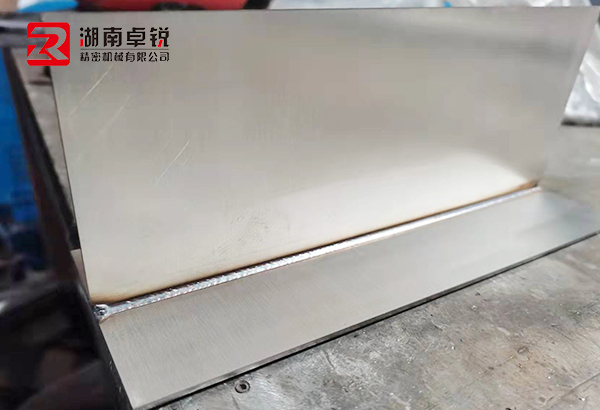

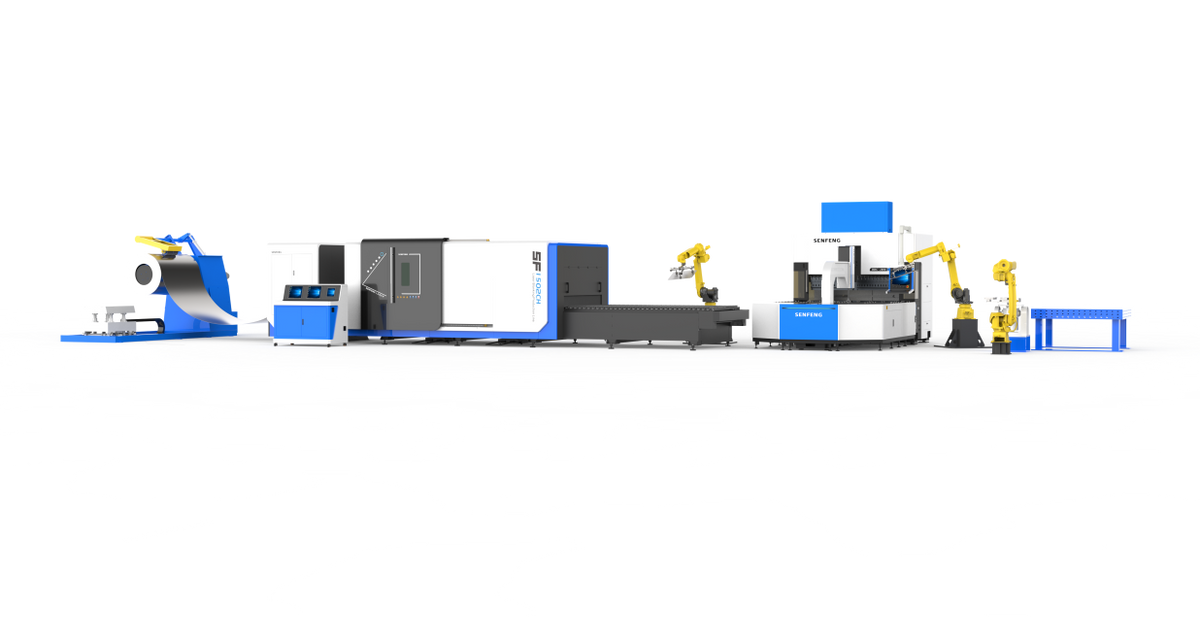

In addition, sheet metal processing also includes standards for multiple process steps, such as CNC cutting, CNC punching, CNC bending, welding, spraying, packaging, labeling, etc. Xiangtan Zhuorui Precision Machinery Co., Ltd. specializes in sheet metal processing, laser cutting, numerical punching processing, CNC bending, sheet metal shell processing, welding processing, as well as various communication equipment cabinets, chassis, industrial electromechanical equipment supporting EMAR cabinets, control cabinets, consoles, pressure furnace welding, railway locomotive parts welding processing, and complete sets of electrical control system assembly. Welcome everyone to consult.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole