Even for Metal Stamping parts with product drawings, designers should be cautious during the design process, because if problems arise during this process without being discovered, subsequent problems will follow one after another, which is a great waste of time, energy, and cost. Therefore, designers need to pay attention to the following points during the design process:

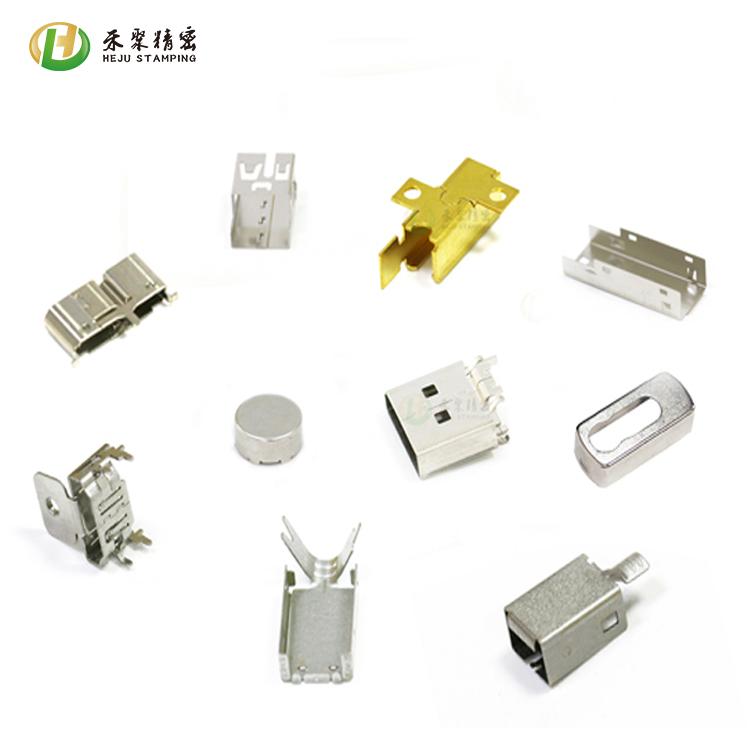

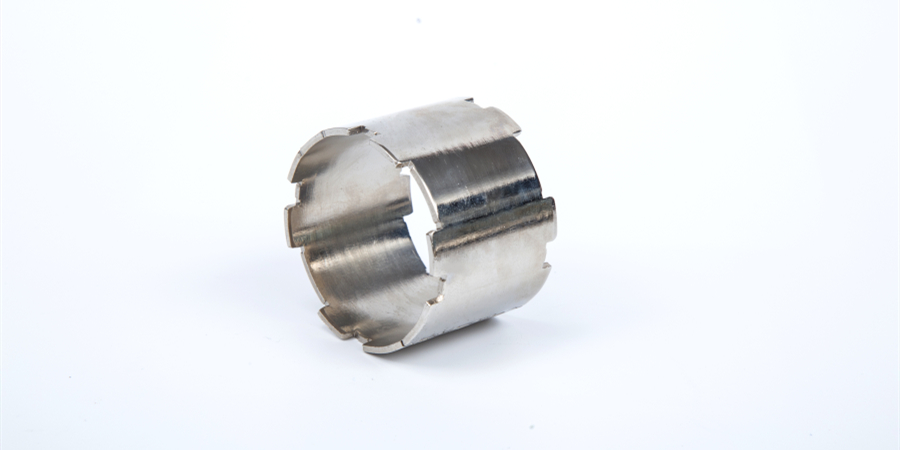

1. The planning of metal stamping parts must meet the application and skill functions of the product;

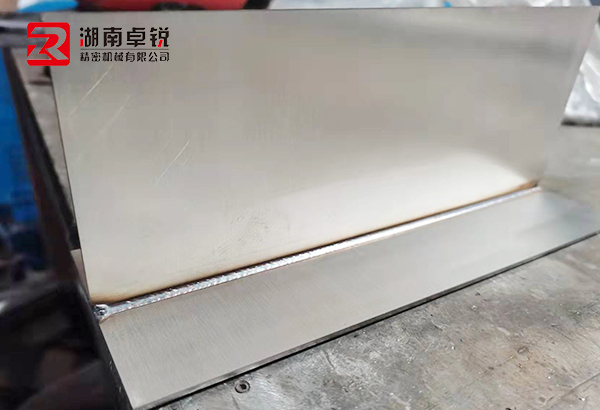

2. The planning structure of metal stamping parts should be reasonable, with simple shapes, which is conducive to simplifying the mold structure, reducing processing steps, and facilitating stamping operations. In order to improve production power, mechanization and automation production can be achieved;  3. Planning for metal stamping parts, while ensuring normal use, should aim for lower precision and surface roughness levels to facilitate the exchange of precision metal stamping products, reduce waste generation, and ensure stable product quality;

3. Planning for metal stamping parts, while ensuring normal use, should aim for lower precision and surface roughness levels to facilitate the exchange of precision metal stamping products, reduce waste generation, and ensure stable product quality;

4. The planning of metal stamping parts should be conducive to improving the utilization rate of metal materials, reducing material waste, and allowing for the use of low-cost materials while minimizing the use of scrap materials in stamping parts.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole