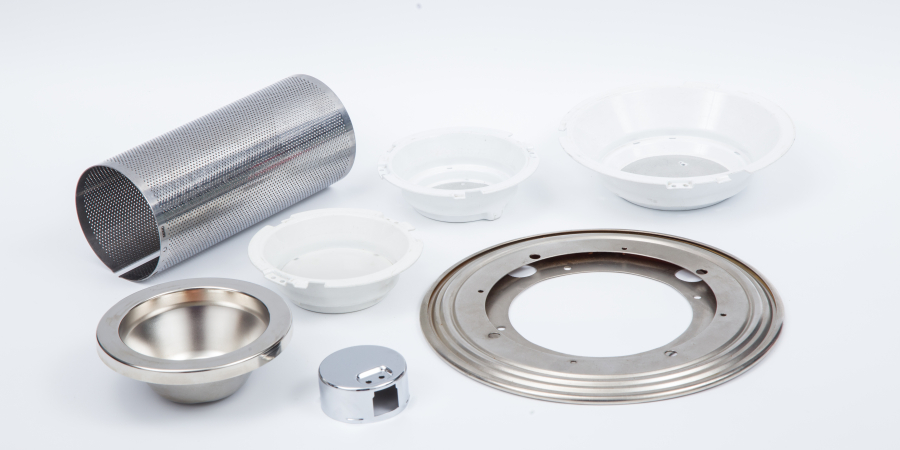

The materials used in manufacturing Metal Stamping parts generally depend on the requirements of production design and functionality. When selecting metal stamping part materials, it is necessary to scientifically and reasonably evaluate the stamping function of the materials, correctly grasp the connection between sheet metal stamping function and stamping forming process. Below are a few metal stamping part materials:

1 Hot rolled steel plate

Hot rolled steel is a high-quality carbon structural steel with a carbon mass fraction of 0.1% to 0.15%. It belongs to low carbon steel and is cheaper in price compared to cold-rolled steel plates. It has higher thickness and strength, and therefore has a wide range of applicability in the stamping field, especially in automotive hardware stamping parts. Hot rolled steel plates occupy a considerable share and are commonly used in crossbeams, longitudinal beams, chassis structural parts, support parts, and parts with high manufacturing formability requirements;

2 Cold rolled steel plate

There are many classification methods for cold-rolled steel plates, which can be divided into boiling steel, killed steel, and semi killed steel according to deoxidation methods; According to the steel type and alloy composition, it can be divided into low-carbon steel, low-alloy high-strength steel, phosphorus added steel, ultra-low carbon void free atomic steel, etc; According to the strength level, it can be divided into ordinary strength level and high strength level; According to the stamping grade or purpose, it can be divided into general use, stamping use, deep stamping use, extra deep stamping use, and ultra deep stamping use;  III. Stainless Steel

III. Stainless Steel

Stainless steel refers to high alloy steel with a chromium mass fraction of over 11%. Its main characteristics are high corrosion resistance and heat resistance, as well as rust resistance and external luster. Stainless steels used in stamping include ferritic stainless steel, austenitic stainless steel, and martensitic stainless steel. The stamping function of ferritic stainless steel is similar to that of cold-rolled steel plate. In the production process of this stainless steel, texture structure can also be obtained by hot rolling, cold rolling, and annealing, which has outstanding deep drawing function. But its hardening index is about 92, and its elongation is 25%~30%, both of which are smaller than austenitic stainless steel, so its elongation type stamping forming function is poor; Among them, ferritic stainless steel represented by SUS430 and austenitic stainless steel represented by SUS304 can be used for stamping forming;

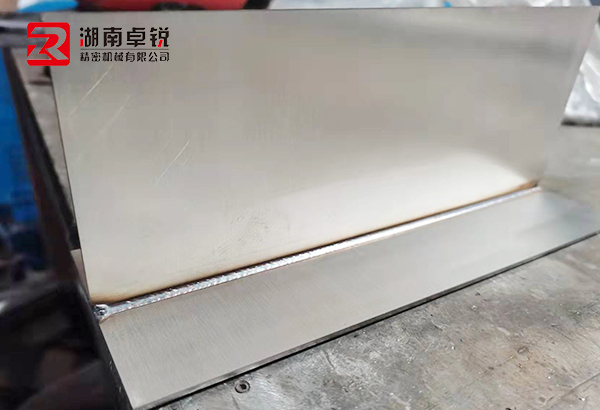

4 Coated steel plate

In order to prevent corrosion of metal stamping parts by various acidic or alkaline substances such as air, moisture, water, oil, etc., countries such as the United States and Japan have proposed the goal of five years of corrosion resistance and ten years of resistance to through-hole rust on the exterior of automobile bodies, and have developed new coated steel plates. At present, most domestic cars also require the use of different specifications and quantities of coated steel plates; The anti powdering and peeling properties of coated steel plates during stamping can affect their formability. There are two types of coating detachment: the first is the formation of particles due to internal failure of the coating, with particle sizes generally smaller than the thickness of the coating, and detachment in powder form, known as powdering; The second type is the formation of flake like particles due to adhesion failure between the coating and the substrate. The particle size is generally similar to or greater than the thickness of the coating, and falls off in a flake like manner, which is called detachment. The size and method of coating pulverization and detachment are related to factors such as coating composition, function, structure, thickness, and forming conditions.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole