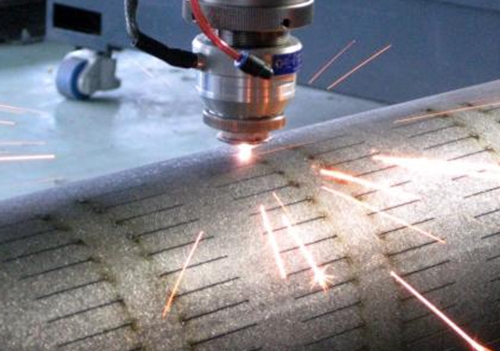

A five axis CNC Machining center is a CNC machine tool that integrates milling, precision milling, precision boring, drilling, and reaming, and can process various types of sheet metal, molds, and other small and medium-sized hardware parts. Commonly used for processing aerospace components such as fuselage parts, impellers, blades, spiral grooves, and other high-precision parts, as well as medical equipment, inclined slots, slanted holes, and miscellaneous curved hardware parts.

It is necessary to meet the following conditions for the normal operation of five axis CNC machining CNC machine tools: the power supply voltage of the five axis machine tool has little fluctuation, the ambient temperature is below 30 ℃, and the relative temperature is below 80%.

1. Requirements for positioning environment of five axis CNC machining CNC machine tools

The orientation of the five axis CNC machining machine should be away from the oscillation source. Avoid direct sunlight and thermal radiation, as well as humidity and airflow. If there is an oscillation source near the machine tool, anti vibration grooves should be set up around the machine tool. Otherwise, it will directly affect the accuracy and stability of the five axis linkage machining CNC machine tool, causing poor contact of electronic components, forming problems, and affecting the reliability of the machine tool.

2. Power requirements for five axis machining CNC machine tools

Generally speaking, CNC lathes are installed in machine tool workshops, which not only have large temperature changes and poor operating conditions, but also various mechanical and electrical equipment can cause significant fluctuations in the power grid. Therefore, the installation orientation of the five axis CNC lathe requires strict control of the power supply voltage. The voltage fluctuation of the power supply should be within the allowable range and remain relatively stable. Otherwise, it will affect the normal operation of the CNC system.

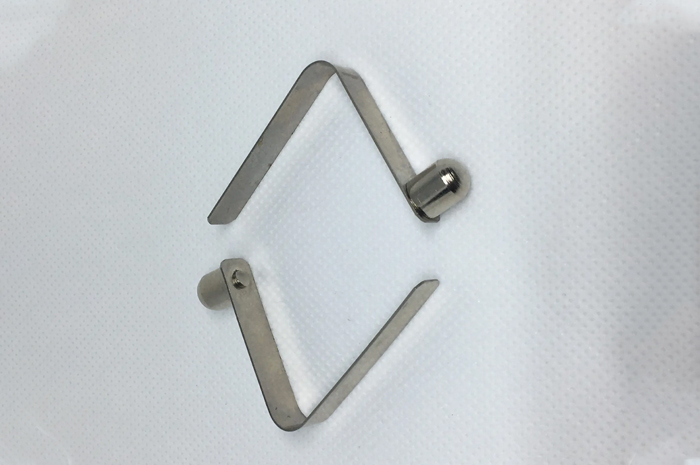

Stainless steel five axis machining

3. Temperature conditions of five axis machining CNC machine tools

The environmental temperature of the CNC lathe is less than 30 degrees Celsius, and the relative temperature is less than 80 inches. Generally speaking, CNC electronic control boxes have exhaust fans or cooling fans to maintain the operating temperature of electronic components, especially when the CPU is constant or the temperature difference is not significant. High temperature and humidity can reduce the service life of control system components and increase the frequency of malfunctions. With the increase of temperature and humidity, the addition of dust will combine with the integrated circuit board, forming a short circuit.

4. Use a five axis machine tool according to instructions

The manufacturer cannot change the parameters set in the control system of a five axis CNC machining machine when it is in use. The setting of these parameters is directly related to the dynamic characteristics of the machine tool. Only the gap correction parameters can be adjusted according to the actual situation. And users are not allowed to privately replace accessories such as hydraulic chucks and machine tools that exceed specifications. In the setting of parts, the manufacturer fully considers the parameter matching of each link. If replaced arbitrarily, the parameters of each link may become inconsistent, which may lead to accidents.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole