Sheet metal parts are a common type of component that can be applied in various fields. Its processing technology usually includes welding and laser cutting, and it has the advantages of light weight, good hardness, and high precision. Generally speaking, the thickness of Sheet Metal Processing is within 6mm. According to various processing techniques, it is processed into various specifications of components. When cold working is applied to sheet metal parts, the thickness of the structural parts can be changed to a more stable thickness. Of course, different types of sheet metal materials need to be selected for different needs of sheet metal processing. Below, Guermei will take you to understand the commonly used materials in sheet metal processing.

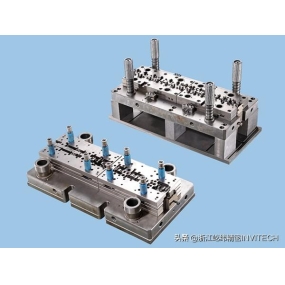

Customized sheet metal shell

In general, the materials used for sheet metal processing mainly include stainless steel plates, galvanized steel plates, aluminum and other raw materials. Different sheet materials require different processing techniques and are used in different ways.

1、 Stainless steel profiles.

(1) Cold rolled steel plate. It is a sheet metal that is processed by controlling the temperature, lowering it below the recrystallization temperature, and then rolling it thin. In sheet metal that has undergone cold rolling processing. Its surface is relatively smooth and has a uniform sheet thickness, making it easy to form. It can be coated with paint or electroplated, while expanding the range of use of the sheet.

(2) Hot rolled steel plate: This plate processing method involves processing the initially rolled or cast slab, heating it, and then removing phosphorus to form a rough rolled steel plate. In general, there is a slight deviation in the thickness of hot-rolled steel plates, and edge pressing may occur during the specific processing process.

2、 Galvanized steel plate. Galvanized steel plates are usually galvanized on the surface of the plate. In general, the thickness of the galvanized layer on the steel plate needs to be controlled at 10 μ Above m, this can prevent damage such as rust on the surface of the board.

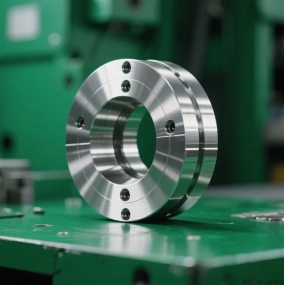

Manufacturer of chassis and cabinet

3、 Aluminum sheet, usually processed on its surface, can also undergo chemical and conductive oxidation treatments, and is widely used in the production of chassis and cabinet casings.

The above are the commonly used materials for sheet metal processing. The process of sheet metal for different chassis and cabinet casings also varies, so when processing sheet metal parts, we need to choose based on our specific application situation.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque