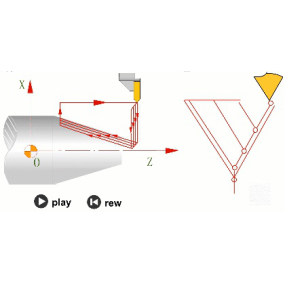

Sheet Metal Processing is divided into production cutting, stamping, bending, forming, welding, polishing, spraying, printing, assembly and other processes. Let‘s introduce the process knowledge of stamping in detail. Stamping processing technology is a fiber laser cutting production and processing method for metal materials.

Its important focus is on metal materials, which are forced to deform or separate by pressure equipment such as stamping machines to obtain the actual required product parts, collectively referred to as stamped parts. There are various situations in the stamping process of molds, and here I will summarize a wide range of stamping processes for everyone.

Punching is a general term for a stamping process that extracts data. It includes: cutting, punching, punching, grooving, slicing, chiseling, edge pressing, cutting, etc. The primary focus of exterior planning is to eliminate excess materials and ensure that the stamping process meets the requirements of the specifications and models.

Cut the tongue to make a cut in a certain part of the guess, but not all of it is cut. It is commonly seen as cutting only three sides of a rectangle while keeping one side still, and its primary function is to set the step distance. The process of expanding the mouth is not widespread, and it is common to see the process of expanding the end or a certain end of a tubular part outward into a trumpet shape.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque