Precision Sheet Metal Processing is a specialized mechanical process used to produce various precision metal components. It is suitable for various fields such as electronics, communication, aerospace, medical equipment, etc. The following is the specific operation process of precision sheet metal processing.

Design: Firstly, product design needs to be based on the customer‘s needs and requirements. During the design process, factors such as the shape, size, material, and processing method of the product should be considered. Common design software includes CAD and SolidWorks.

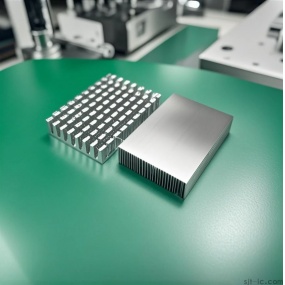

Material preparation: Obtain corresponding metal sheets from suppliers according to design requirements. Common metal materials include stainless steel, aluminum alloy, copper, titanium, etc. The selection of materials should take into account the product‘s usage environment and requirements, as well as the difficulty of processing.

Plate cutting: Cut the purchased metal plates into the required size and shape according to the design requirements. There are various cutting methods, such as shearing, cutting machinery, planers, etc. When cutting, it is necessary to maintain the flatness and accurate size of the board.

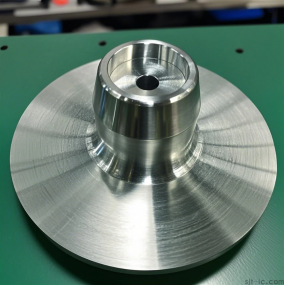

Surface treatment: The cut sheet is subjected to surface treatment to remove burrs, rust, and other debris generated during the cutting process. Common surface treatment methods include grinding, polishing, electroplating, etc. Surface treatment can improve the aesthetics and durability of products.

Surface treatment: The cut sheet is subjected to surface treatment to remove burrs, rust, and other debris generated during the cutting process. Common surface treatment methods include grinding, polishing, electroplating, etc. Surface treatment can improve the aesthetics and durability of products.

Bending and Forming: Bending and forming the surface treated sheet metal. This process requires the use of mechanical equipment such as bending machines, punching machines, etc. Bending and forming should be carried out according to design requirements and the intended use of the product to ensure its accuracy and quality.

Welding and connection: If the product requires welding and connection, welding technology can be used to connect different components. The commonly used welding methods include argon arc welding, laser welding, etc. The welding process should pay attention to the compactness and welding strength of the weld seam.

Assembly and debugging: Assemble the welded components according to the design requirements. During the assembly process, attention should be paid to the precise fit of components and the accuracy of connection methods. After assembly, debug and test the product to ensure its normal functionality and stable performance.

Surface coating and treatment: If the product requires surface coating and treatment, methods such as spraying and plastic spraying can be used. Painting and treatment can increase the aesthetic and protective properties of products, and improve their corrosion resistance and wear resistance during use.

Inspection and quality control: Quality inspection must be conducted at every stage of the processing to ensure the quality of the product. Common inspection methods include dimensional measurement, visual inspection, material testing, etc. Only products that pass the inspection can proceed to the next process.

Packaging and Shipping: After Z, the processed products are packaged for transportation and delivery to customers. During the packaging process, attention should be paid to protecting the surface of the product from damage and ensuring that the product is not impacted or squeezed during transportation.

The above is the specific operation process of precision sheet metal processing manufacturers. Throughout the entire process, it is necessary to strictly adhere to operating procedures and quality control requirements to ensure that the quality and performance of the product meet the customer‘s needs and standards. Precision sheet metal processing requires experienced engineers and technicians to operate to ensure the accuracy and efficiency of the processing process.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque