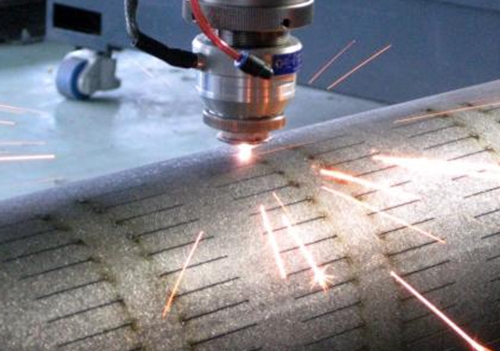

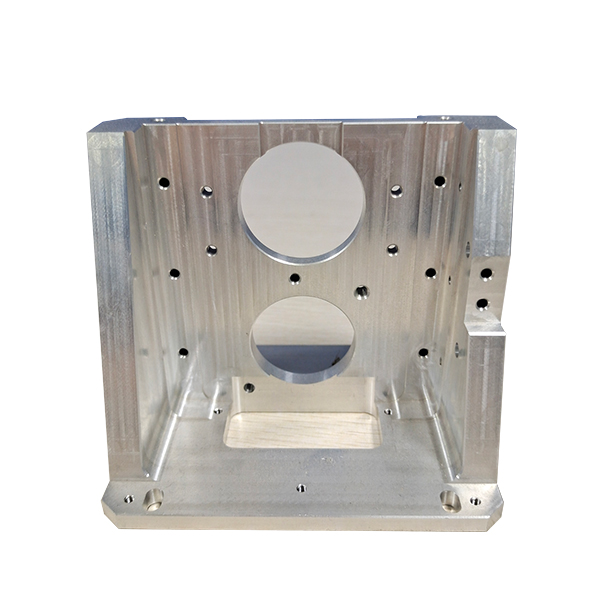

Optical communication component processing is a precision manufacturing technology that involves precise machining and manufacturing of various components in optical communication equipment. These components may include fiber optic connectors, optical splitters, optical attenuators, optical switches, etc. The technical difficulties in the processing of optical communication components are mainly reflected in the following aspects: High precision requirements: Optical communication components usually need to achieve very high precision requirements, such as micrometer or even nanometer level precision. This high precision requirement poses great challenges to machining technology. Material handling: Optical communication components often involve special materials such as optical glass, ceramics, etc. These materials have high hardness and are very sensitive to factors such as temperature and stress during processing, which can easily lead to problems such as cracks and deformation. Surface quality: The surface quality of optical communication components has a significant impact on the performance of the equipment. Any surface defect can cause attenuation or distortion of the optical signal. Therefore, how to ensure the surface roughness and flatness of the parts is a technical difficulty in the machining process. Optical performance: The optical performance of optical communication components is their core performance. How to ensure that the optical performance of the components is not lost during the processing, such as transparency, refractive index, etc., is a key technical issue in the processing.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole