Precision hardware processing personnel must pay attention to safety and use the machine correctly during stamping processing to prevent danger:

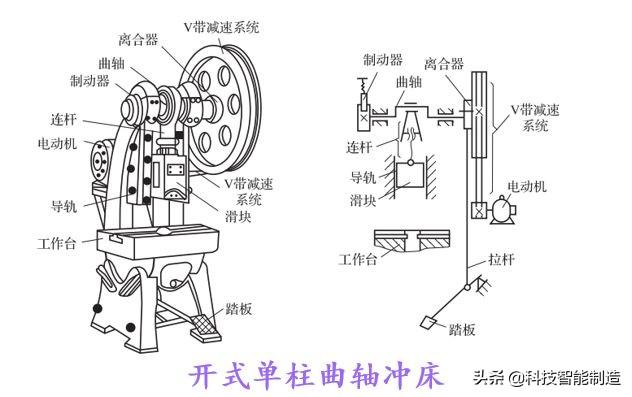

1. Before processing precision hardware components, it is necessary to carefully check whether the punch press protection equipment is intact, and whether the clutch braking equipment is sensitive, safe, and reliable;

2. The objects on the workbench should be cleaned thoroughly to prevent them from falling onto the foot switch during operation, which may cause the punch to accidentally start and injure people;

3. When punching small workpieces in precision hardware processing, hands should not be used, and specialized tools or active feeding equipment should be used;

4. When loading and unloading workpieces, the foot should be disconnected from the foot switch;  5. Prohibit others from lingering around the foot switch;

5. Prohibit others from lingering around the foot switch;

6. If the workpiece is stuck in the mold, a special tool should be used to remove it, and hands should not be used. The foot should be moved away from the foot pedal;

7. After each workpiece is punched, the hand or foot must detach from the button or pedal to prevent accidental operation;

8. When two or more people are operating, one person should give unified command, act together, and cooperate with each other;

9. After the homework is completed, the power should be cut off, the surrounding environment should be cleaned, and the workpieces, things, tools, and molds should be placed neatly.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole