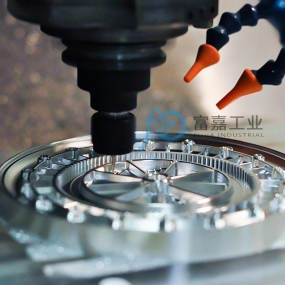

Stamping and stretching oil is a medium viscosity metal processing oil designed for the stretching and stamping of various metals. Contains various extreme pressure, smooth, and rust resistant additives, suitable for automatic processing of low to medium strength steel, as well as non-ferrous metals such as copper and aluminum. The primary effect of stamping stretching oil in the stretching and forming of precision hardware parts is to achieve smoothness between the mold and the precision hardware parts, which belongs to the metalworking fluid. In addition, stretching oil also has cooling, anti-wear, cleaning, and rust prevention effects. The following mainly introduces the functional requirements of stamping and stretching oil in various stages:

1. Stamping process

With the continuous improvement of consumers‘ demands for car safety, lightweight development trends, and exterior appearance, the shape and scale of precision hardware components in car bodies are becoming increasingly chaotic. High strength steel plates that are difficult to form are widely used in car bodies, resulting in frequent cracking or wrinkling during stamping and stretching.

Smoothness, as the primary function of stretching oil, can effectively ensure the smooth progress of stamping and stretching processes, prevent surface cracking and wrinkling, ensure outstanding formability and demolding of steel plates, and prevent scratches and sintering between the mold surface and the steel plate. The improvement of smoothness can improve the functionality of molds, thereby reducing the requirements for metal material grades, allowing the use of lower grade metal materials, and significantly reducing scrap rates, which can save 10% to 20% of metal costs.

To better protect the mold, extend its lifespan, increase stamping speed, and reduce downtime for wiping the mold, stamping stretching oil should also have a certain cooling and cleaning effect.

In the process of car body production, based on the characteristics of stamping production, it is necessary to produce a certain amount of components for inventory for each batch of precision hardware parts. The inventory time of parts varies depending on the production cycle of the enterprise, usually 3-7 days. Therefore, stretching oil should also have anti rust function to ensure that the parts do not rust on the surface during the production cycle.  2. Welding and assembly process

2. Welding and assembly process

Stamping and stretching oil should be able to meet the requirements of oil welding in welding production, and the welding points of oil welding should meet the product requirements, without any welding quality problems such as virtual welding or false welding. During the production process, there should be no or minimal occurrence of oil fumes to prevent any impact on workers‘ health and working environment.

3. Painting process

Precision hardware components coated with stretching oil during the painting process must meet the requirements of pre-treatment degreasing and cleaning processes, so that the stretching oil can be removed after the pre-treatment process without affecting the subsequent phosphating, electrophoresis, and intermediate coating processes. If the stretching oil cannot be completely cleaned and there is oil stains on the surface of precision hardware parts, the oil stains will be carried into the phosphating solution and contaminate the phosphating tank solution. Due to the presence of oil stains in some areas, the quality of the surface film will be poor, with uneven thickness. In severe cases, it may even form a coating layer, resulting in incomplete oil removal and posing significant risks to the coating quality.

4. Environmental Protection

The use of stretching oil should reduce its environmental impact on the production workshop, minimize the generation of waste and industrial wastewater, and have low toxicity, so as not to cause physical injury to workshop workers.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque