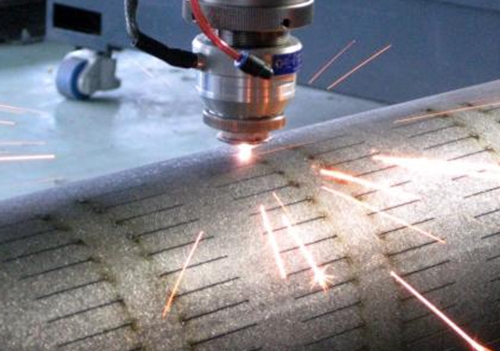

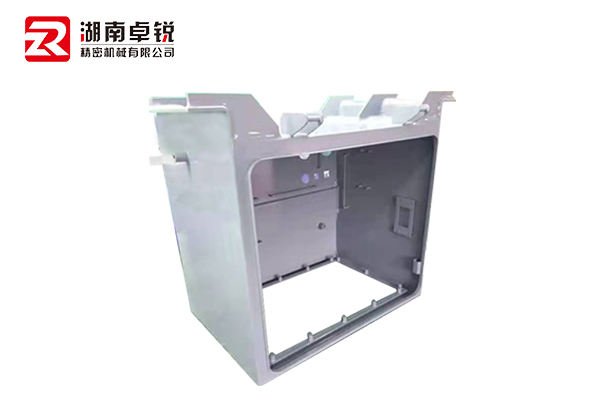

Sheet metal shell processing is a widely used processing method in various industries, mainly used for manufacturing various shells and boxes. The main application areas of sheet metal shell processing will be introduced below.

In the field of electronic and communication equipment, sheet metal shell processing is widely used. For example, the shells of electronic products such as mobile phones, computers, and routers are usually manufactured using Sheet Metal Processing, which has excellent appearance and structural stability.

In the field of home appliances, sheet metal shell processing is also widely used in the home appliance industry, such as the manufacturing of shells for refrigerators, washing machines, air conditioners, and other products. Sheet metal shell processing has the characteristics of high manufacturing accuracy, beautiful appearance, and good durability, which can meet the requirements of home appliances for shells.

Automotive industry: Sheet metal shell processing also has important applications in the automotive industry. For example, parts such as car body shells, engine covers, and doors are all manufactured using sheet metal processing. Sheet metal processing can provide lightweight and high-strength shells for automobiles, while also meeting various complex styling requirements.

In the field of mechanical equipment, sheet metal shell processing is also widely used. For example, the shells of equipment such as machine tools, workbenches, and chassis are usually manufactured using sheet metal processing. Sheet metal processing can meet the structural strength and appearance requirements of mechanical equipment, and can also be customized according to different mechanical equipment needs.

New energy industry: With the rapid development of the new energy industry, sheet metal shell processing has also been widely used in this field. For example, the shell of solar panels, the tower and nacelle of wind power generation equipment are all manufactured using sheet metal processing. Sheet metal processing can meet the requirements of new energy equipment for the shell, making it have excellent anti-corrosion and durability.

In the field of medical equipment, sheet metal shell processing also has important applications. For example, the shells of medical devices and the brackets of surgical equipment are all manufactured using sheet metal processing. Sheet metal processing can meet the requirements of medical equipment for appearance, structural stability, and durability, ensuring the stable operation and safety of the equipment.

Optoelectronic industry: Sheet metal shell processing technology is also widely used in the optoelectronic industry. For example, the casings of optical instruments and display screens are all manufactured using sheet metal processing. Sheet metal processing can ensure the stability and durability of optical instruments and display screens, while also meeting their requirements for the optical performance of the casing.

In the field of architectural decoration, sheet metal shell processing is also applied. For example, the shells of building doors and windows, as well as the shells of various interior decoration materials, are all manufactured using sheet metal processing. Sheet metal processing can be customized according to the needs of building decoration, providing products with good appearance and structural stability.

In summary, Zhuzhou Sheet Metal Processing Company tells you that sheet metal shell processing has a wide range of applications in various fields. It can not only meet the requirements of appearance, structural stability, and durability for products, but also be customized according to the needs of different industries, promoting the development of various industries.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole