The problem of laser cutting incoherence may not have been found yet.

To solve the problem of laser disconnection, we should solve the problem of disconnection by cutting. Regarding the disconnection by programming error, the designer is required to have high quality. In the process of compiling the cutting program, we should carefully check the fault. Regarding the disconnection problem caused by the ventilation body, through the accumulation of actual operations, when the ventilation bottle is re-cut, we should cut at a speed of 5% of the normal cutting speed, and press the start key and the speed key together to continue cutting.

Increasing the replenishment refers to adding a small piece of replenishment at the cutting sharp corner. This method can not ablate the sharp corner, and the scale of the sharp corner will not change. Regarding the model with the sharp corner on the outside, adding the replenishment can not only harm the user during use, but also avoid being touched during use.

We have now analyzed the reasons for the impermeability of the laser cutting process, and we will propose corresponding solutions for these reasons. Regarding the problem of small current of laser power drop, we need to change the laser tube in time, and slide a larger voltage regulator to output the output power of the laser current. To properly cut the speed, clean the contaminated mirror in time and reasonably, and replace the aggregated lens.

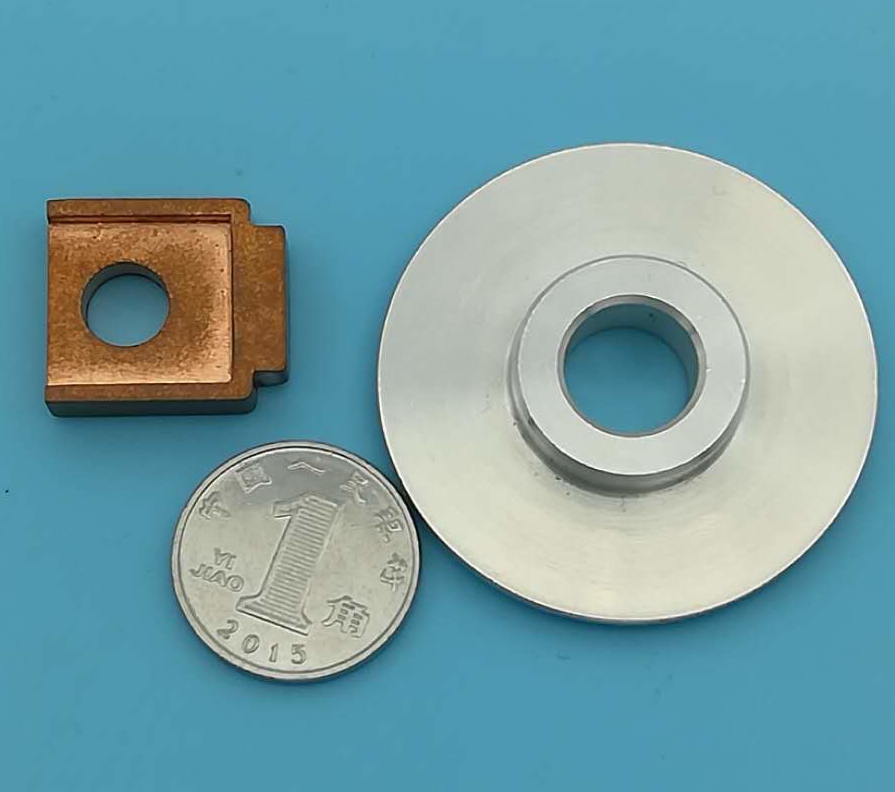

For the problem of optical path error, the optical path can be readjusted, and the focal length can be adjusted until the laser shines a very round light on the paper. Also pay attention to polishing the surface of copper and aluminum in advance or coating light-absorbing materials to deal with the problem of high reflectivity when cutting.

Check whether the laser power switch of the machine is turned on; check whether the light output signal, control signal and water maintenance signal of the chiller are normal; check whether the light output of the laser tube is normal; the weak light (purple) is abnormal, and the normal is pink; check whether the water flow of the laser tube is normal; check whether the light path is normal, press the light to check whether the laser tube is bright, but the laser head is not light, then the light path is difficult.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole