What problems should be paid attention to in Sheet Metal Processing of imitation EMAR cabinets? The sheet metal processing manufacturer will answer it.

The sheet metal processing of imitation EMAR cabinets needs to pay attention to the following issues: sheet metal shell processing

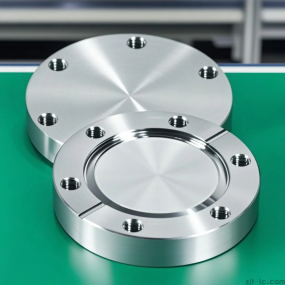

1. Material selection: Sheet metal processing requires the selection of suitable materials, such as stainless steel, aluminum alloy, etc. For imitation EMAR cabinets, similar metal materials need to be selected to ensure consistency in appearance and performance.

1. Material selection: Sheet metal processing requires the selection of suitable materials, such as stainless steel, aluminum alloy, etc. For imitation EMAR cabinets, similar metal materials need to be selected to ensure consistency in appearance and performance.

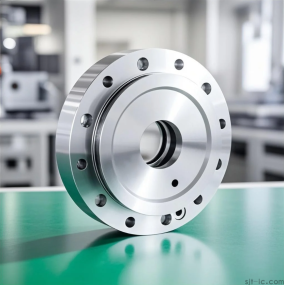

2. Design specifications: Before sheet metal processing, it is necessary to design according to the product design specifications, including size, shape, function and other requirements. It is necessary to ensure that the design meets the process requirements and can be processed with existing sheet metal processing equipment.

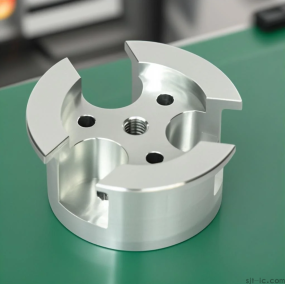

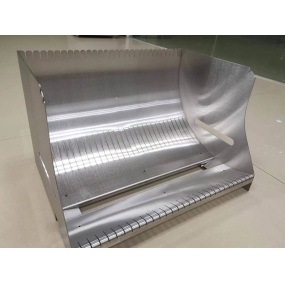

3. Process technology: Sheet metal processing requires mastering certain process technologies, including die design, stamping, bending, welding, surface treatment, etc. In sheet metal processing of imitation EMAR cabinets, it is necessary to master the details, such as the handling of corners and the embedding of parts.

4. Machining accuracy: Sheet metal processing requires high machining accuracy, especially in large-scale sheet metal processing. In sheet metal processing of imitation EMAR cabinets, it is necessary to ensure the consistency of component accuracy and avoid the accumulation of errors.

5. Planned control: Sheet metal processing requires planned control, including processing time, process flow, machinery and equipment, etc. In sheet metal processing of imitation EMAR cabinets, it is necessary to reasonably arrange the production plan to ensure on-time delivery of parts and product quality.

In short, the sheet metal processing of imitation EMAR cabinets requires comprehensive consideration and mastery from material selection to product design, from process technology to processing accuracy. Only by achieving a rigorous, standardized and scientific sheet metal processing process can we ensure the maximum quality and efficiency of products.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque