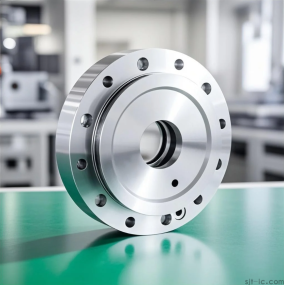

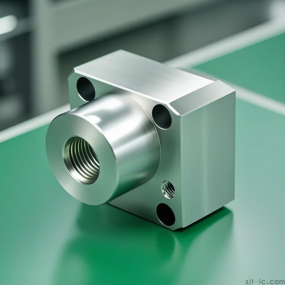

Numerical control five-axis machining center is a kind of high-tech processing equipment, mainly used for processing complex curved surfaces. It has five axis linkage, which can process various irregular shapes of parts in an all-round way and with high precision. The high-precision machining of numerical control five-axis machining center is mainly realized through the following aspects: Error synthesis method: By measuring the original errors of each axis of the machine tool, and using high-precision measuring instruments such as laser interferometer, after synthesizing the errors, measures are taken to eliminate or reduce these factors.  Error Transfer Method: By transferring the geometric errors, force deformation and thermal deformation of the process system, etc., so that it does not affect the processing accuracy. For example, using a fixture to transfer the original error of the machine tool spindle to the aspect that does not affect the machining accuracy. Error Average Method: Using the mutual comparison and mutual correction between closely related surfaces, or using each other as a reference for machining, in order to achieve the purpose of eliminating machining errors. Direct Reduction of Original Error Method: After identifying the main original error factors that affect machining accuracy, try to directly eliminate or reduce them. For example, using the large feed reverse turning method, the bending deformation caused by axial cutting force is basically eliminated. The above measures have significantly improved the machining accuracy of the numerical control five-axis machining center. For more information, it is recommended to consult a professional.

Error Transfer Method: By transferring the geometric errors, force deformation and thermal deformation of the process system, etc., so that it does not affect the processing accuracy. For example, using a fixture to transfer the original error of the machine tool spindle to the aspect that does not affect the machining accuracy. Error Average Method: Using the mutual comparison and mutual correction between closely related surfaces, or using each other as a reference for machining, in order to achieve the purpose of eliminating machining errors. Direct Reduction of Original Error Method: After identifying the main original error factors that affect machining accuracy, try to directly eliminate or reduce them. For example, using the large feed reverse turning method, the bending deformation caused by axial cutting force is basically eliminated. The above measures have significantly improved the machining accuracy of the numerical control five-axis machining center. For more information, it is recommended to consult a professional.

Hello! Welcome to EMAR's website!

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque