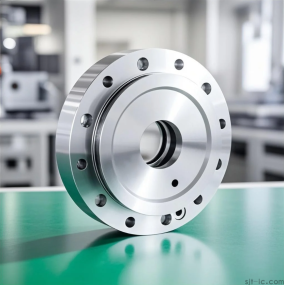

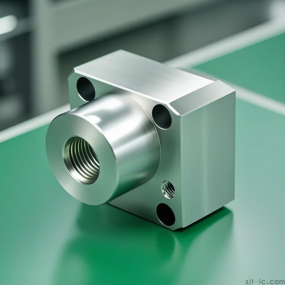

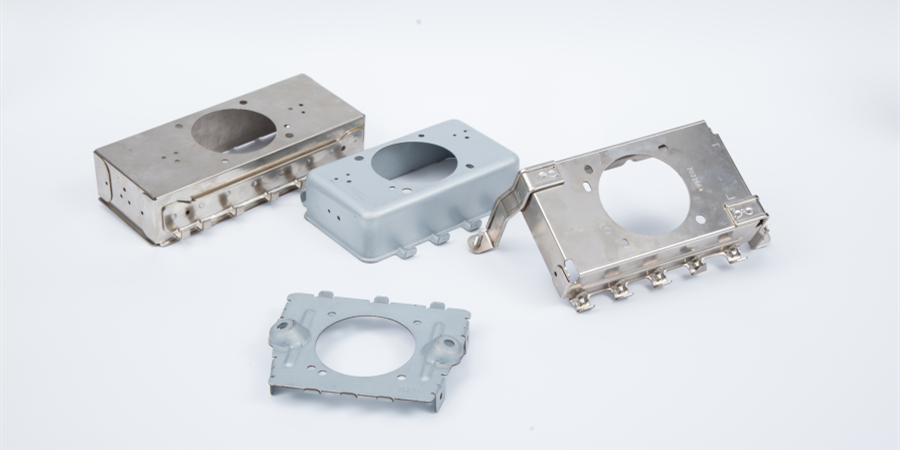

The craftsmanship of a bent part refers to the adaptability of the bent part to the stamping process, that is, whether the structural shape, size, accuracy requirements, and materials used in the bent part meet the processing requirements of the stamping process.

Generally speaking, bending parts with excellent craftsmanship can ensure that the material consumption is small, the number of processes is small, the mold structure is simple, the product quality is stable, the cost is low, and the technical preparation work and production organization are economical and reasonable; In the process design, the first analysis of the craftsmanship of the bending parts is to lay the foundation for the formulation of the process program.  The craftsmanship of bending parts mainly includes the following two aspects:

The craftsmanship of bending parts mainly includes the following two aspects:

1. Conduct a process review of the stamping product drawing, and carefully analyze and study the shape characteristics, size, and accuracy requirements of the bending parts according to the product drawings. The mechanical properties, process properties, and performance of the materials used may cause springback, warping, crooked, and slack, so as to understand their impact on the difficulty of stamping processing. When analyzing the product drawing, special attention should also be paid to the limit dimensions of the parts (such as the minimum punching scale, the minimum narrow groove width, the minimum hole distance and hole edge distance, the minimum bending radius, the minimum drawing fillet radius, etc.), scale tolerances, design benchmarks, and other special requirements.

2. If it is found that the workmanship of the bending parts is poor, the product designer should work with the product designer to make appropriate corrections to the shape, size, accuracy requirements, and even the selection of raw materials of the bending parts without affecting the use of the product. If necessary, the product design part should be recommended to be redesigned from scratch.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque