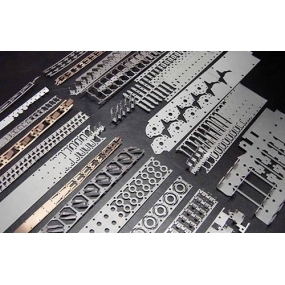

Five-axis precision part machining is the precision of making complex precision metal parts in a CNC Machining plant. In a five-axis CNC machine tool, the tool moves in the X, Y, and Z axes, as in a three-axis machine. In addition, the table can rotate around the X and Y axes. Key to these rotation planes are respectively called A and B axes. These additional rotations are opened, and other surfaces are now impossible to load.

Five-axis CNC machines in five-axis parts processing plants can perform precise 3D machining because the machine moves on the X and Y axes, not the A and B axes. The use of high-quality five-axis CNC machining centers has many advantages for the production of complex parts. Five-axis numerical control machining is very popular in the aviation, aerospace, automotive and energy industries. It can handle other machining methods, and even narrow boxes with various curved geometries that cannot be concealed. It greatly shortens the delivery time.

The five-axis CNC machine is very fast to make high-precision precision parts machining, it does not require repeated fixture changes and program modifications. In a single machining process, it can create incredibly complex shapes, ultra-high surface finish, five-axis machining can achieve cleaner, more accurate cutting, and then obtain surface finish. The only drawback of five-axis CNC machining is the high cost, and the excellent service and features it provides make it more impressive than three-axis and four-axis machining, but for precision parts machining that requires ultra-high quality, the extra cost is worth it.

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque