Do you really understand the methods of laser cutting?

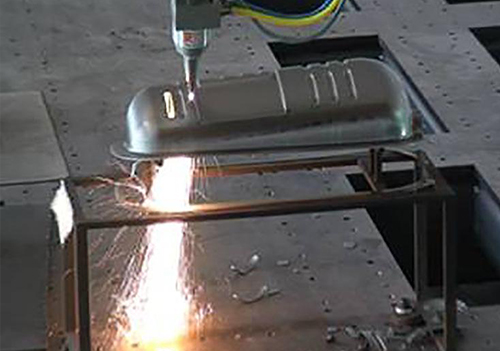

Oxygen cutting: Oxygen, as an accelerant, can react violently with the metal heated by the laser to melt, generating a lot of oxidation heat, so in fact oxygen cutting is an "aerobic" version of melting cutting. Because metal combustion generates heat, oxygen cutting saves more energy than melting cutting, but the cutting speed is much higher than melting and vaporization cutting. Oxygen cutting is mainly used to cut carbon steel, titanium steel and other easily oxidized metal materials.

Scribing and controlled cracking: Scribing is the use of a high-energy density laser to scan the surface of a brittle material. After the material is heated, it evaporates into a small groove, applying a certain pressure to the material, causing the brittle material to crack along the small groove.

Controlled cracking is the steep temperature distribution produced by laser grooving, which generates partial thermal stress in brittle materials, causing the materials to crack along small grooves. For example, glass cutting.

The current use of laser cutting equipment in the market is divided into two categories: metal and non-metal.

It is a metal laser cutting machine used to make large equipment such as decoration, advertising, lamps, kitchen utensils, thin plates, electrical cabinets, elevator panels, engineering boards, and concave-convex switchgear.

Non-metallic laser cutters refer to equipment used to cut plastics (polymers), rubber, wood, paper products, leather, and natural or synthetic organic materials, because these items are not metal products and therefore absorb laser light differently. Therefore, this material is cut with a CO2 laser cutter.

Simply put, a laser is a focused beam of light that puts a lot of energy into a small area. When this happens, the material in front of the laser burns, melts, or vaporizes, forming a hole. Add some CNC to it and you get a machine that can cut or carve very complex parts made of wood, plastic, rubber, metal, foam, or other materials.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole