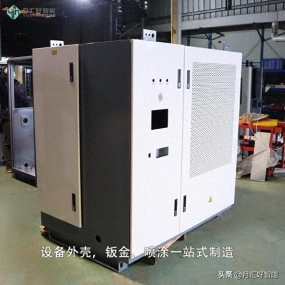

Not only the requirements of customers, but also the production quality requirements of stamping and bending parts are very strict, and we must strictly control the shape and size of the products.

First, the requirements for bending parts

1. The shape of the bending parts should be as symmetrical as possible, and the bending radius should not be less than the minimum bending radius allowed by the material.

2. Bend the punched parts with holes to avoid deformation of the holes.

3. The curved edge is too short to form; therefore, the straight part of the curved edge should be H > 2. If H is required to be very short, an appropriate margin should be set aside to increase H, and then the increased metal should be cut after bending. Requirements for deep drawing and stamping parts

1. The shape of the deep-drawn stamping part should be simple, symmetrical, and the depth should not be too large, so as to minimize the number of deep-drawn parts and make it easy to form.

2. If the fillet radius of the deep-drawn stamping parts is not increased, the number of deep-drawn and shaping work will be increased, and the number of stamping parts molds will also be increased. It is also easy to generate waste and increase production costs.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque