Optical precision CNC Machining is essential to the invention of the modern optical profession. We use CNC machining to make optical precision parts. At Weimat, we supply 3-axis and 5-axis CNC machines. Optical parts are increasingly...

Optical precision CNC machining is essential to the invention of the modern optical profession. We use CNC machining of optical precision parts. At Wimat, we offer 3-axis and 5-axis CNC machining. Optical parts are getting more and more messy, so they need to be processed. With it comes a new era of optical precision machining. When creating non-messy optical parts, we have several common methods. It requires polishing and normal grinding procedures. However, we can only partially create messy optical parts using these conventional methods. This is due to their lack of dimensional accuracy. In this case, our team of experts chose to use multi-axis machining.

Miniature and aspherical optics usually require very rigorous service. Fortunately, the precision cutting process provides this required precision. They use diamond tools on ultra-precision tools to achieve this goal. As a result, we finally achieve rigorous service and high surface finish. We use this method to achieve proper scale accuracy for optical parts and their molds. This is a further insight into this.

What are the ultra-precision production methods for optical parts?

There is an aspirational way to make messy micro-optical components. This is to achieve surface quality of a fraction of a micron Ra together. It requires the use of ultra-precision tools and diamond cutters. Acquiring free-form surfaces, messy shapes, and real 3D parts requires expertise. We sometimes have to use some unique multi-axis machining methods.

Machinists use very few methods in optical precision machining. These include laser machining, EDM, grinding, micro-cutting, and silicon etching. Optical machining requires machining on flat and free-form optical surfaces. Micro-cutting is a method of achieving the desired structural scale, precision, and precision on both optical surfaces.

What are the tool elements of optical precision machining?

Two primary factors determine the production quality of optical parts. These are the roundness and sharpness of the tool. Therefore, it is necessary to include special tool shapes. Among them are ball end mills, diamond mini end mills and other turning and forming tools. There are several ultra-precision cutting methods for optical parts. They are jet cutting, end milling, cut-in cutting and fast tool cutting.

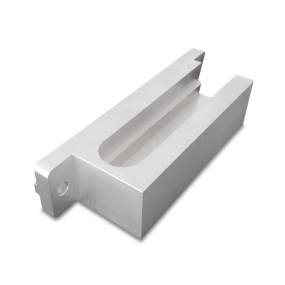

Our team of experts sometimes combine vibration-free CNC machines with compact tool holders and fixtures. This allows a single point of diamond cutting to effectively scrape the material off the workpiece. This method ensures that a very high and concentrated cutting force is applied to the workpiece. As a result, we end up with almost no dents elsewhere, while maintaining perfect shape accuracy and surface finish. This allows us to complete optical precision machining.

What is single-point diamond tool turning? Optical precision machining

We apply this type of machining when we want to achieve rotationally symmetric optical parts. It is one of the effective cutting processes. This method achieves high cutting speeds and high surface finish at Ra less than 5. What we use in this method takes into account the accuracy of the parts in production.

Our experts often calculate the tool radius and the compensation of the entire tool during the machining process. In addition, we need to be very careful when dealing with the accuracy in the sub-micron range. This involves controlling the waviness of things to the level of 0.1um of the east-west radius. At the same time, if we need a simpler surface structure, we will use cut-in cutting with pointed things. These methods help us to achieve optical precision machining.

Numerical control milling

CNC milling is a great choice when machining messy surface shapes. We sometimes use it to finish free-form surfaces. Examples of optical parts we can make include camera lenses and vehicle lighting prototypes. When machining these parts, we need at least a three-axis numerical control machine. In contrast, we need a 5-axis machine to achieve accurate optical surface characteristics. In this case, we use three primary diamond CNC milling tools. They are end mills, jet cutters, and ball end mills.

Ball milling cutters are crucial when dealing with free-form surface features. This is because they can handle geometric shapes up to 0.5mm. Our professional machining services allow us to achieve internal angle accuracy up to R0.1-R0.15mm. Flying cutters are an ideal choice for groove cutting. In addition, we can apply them when dealing with surfaces. For example, we use it for machining laser mirrors and pyramid parts.

What is the key role of optical precision machining in the modern world?

It is worth noting that the demand for optical components is currently at its peak. This is accompanied by a growing consumer market for electronic components. It is worth noting the use of camera lenses in digital SLR cameras, smartphones and printer scanning mirrors. This poses a mission challenge for the market. The first question is how to produce free-form optical components cost-effectively. Fortunately, precision machining allows us to achieve this goal. We eventually replaced the normal camera lens with a single free-form mirror component. This makes it compact and saves production costs at the same time.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque