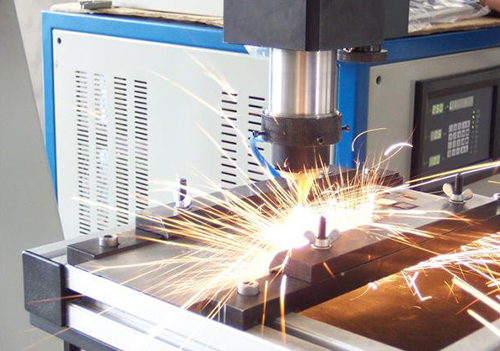

How can laser cutting improve work efficiency?

Focal orientation control is one of them. One of the advantages of laser cutting is the high energy density of the beam of light, so the diameter of the focal light spot is as small as possible to make a narrow slit. Because the smaller the focal depth of the focusing lens, the smaller the diameter of the focal light spot. For high-quality cutting, the effective focal depth is also related to the lens diameter and the cut data. Therefore, it is important to control the orientation of the focus relative to the appearance of the cut data.

Because the laser power density has a great influence on the cutting speed, the selection of lens focal length is an important issue. After the laser beam is focused, the size of the light spot is proportional to the focal length of the lens. After the beam of light is focused by the short focal length lens, the size of the light spot is very small, and the power density at the focal point is very high, which is very favorable for data cutting; but its disadvantage is that the focal depth is very short and the conditioning margin is small, which is generally more suitable for high-speed cutting of thin materials. Because the long telephoto lens has a wide focal depth, it only needs to meet the power density, which is more suitable for cutting thick workpieces.

After confirming which focal length lens to use, the relative orientation of the focal point and the surface of the workpiece is particularly important to ensure the quality of cutting. Because of the high power density at the focal point, in most cases, the focal position when cutting is just at the surface of the workpiece, or slightly below the surface.

During the whole cutting process, ensuring that the relative orientation of the focus and the workpiece is constant is an important condition for achieving stable cutting quality. Sometimes, the lens is heated due to poor cooling and then causes the focal length to change, which requires timely adjustment of the focus orientation. When the focus is in the appropriate orientation, the slit is small, the efficiency is high, and the cutting speed can achieve good cutting results. In most cases, the focus of the beam of light is adjusted to just under the nozzle.

To improve the efficiency of laser cutting machine must also be under the premise of safe production, which is also what every enterprise needs to master. In this way, it can create more value for the enterprise. Do a good job in safe operation and reduce unnecessary losses for the enterprise.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque