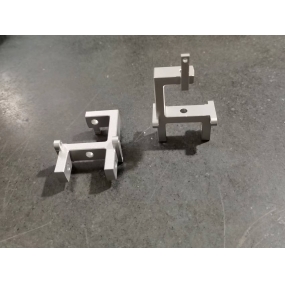

Sheet Metal Processing is a technology and process for manufacturing and processing thin sheet materials. Cutting is one of the basic and important processes of ZUI in sheet metal processing. Cutting refers to the division of the main material of a large sheet into small pieces for subsequent processing. In sheet metal processing, it is often necessary to cut the sheet, and the quality of the cutting process affects the product quality and processing efficiency. The imitation EMAR cabinet sheet metal processing editor will introduce several common sheet metal cutting methods below. Sheet metal processing manufacturers

First, flame cutting

First, flame cutting

Flame cutting is a common processing method, which can melt the plate with flame, and burn with oxygen jet at the same time to produce high temperature, so that the molten metal is oxidized and a large amount of heat energy is released, thereby cutting it off. The cutting speed of this method is fast, which is suitable for processing medium-thick steel plate and iron plate materials, and is suitable for mass production. However, this method will generate a lot of dust and smoke, which has certain safety hazards to stoves, atmospheric environments and operators.

Second, laser cutting

Laser cutting is one of the commonly used and efficient cutting methods of ZUI in modern sheet metal processing. This method uses a laser beam to heat the metal material, melt it and cut thin sheets along a certain cutting path. The advantages of laser cutting lie in its high precision, fast speed, smooth and neat cutting surface, which is suitable for fine cutting of various sheet and sheet materials. The disadvantage is that the cost of equipment and energy is high, which is suitable for medium and small batch production.

III. Shear cutting

Shear cutting is one of the mainstream methods of sheet metal cutting through special equipment. This method is to first place the plate on the machine tool, and then make the steel plate warp and break through pressure. The advantages of shear cutting are fast cutting speed, easy operation, low use cost and low maintenance cost. It is suitable for the processing of steel plate, aluminum plate and stainless steel plate materials in different thickness ranges. However, one of the disadvantages of this method is warping, which will produce certain burrs and irregular shapes at the cutting place.

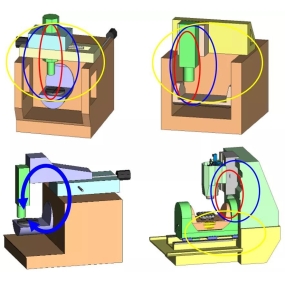

Fourth, machining center cutting

Machining center cutting is a multi-functional sheet metal cutting method. From the operator‘s point of view, it needs to be input to the machining center through CAD file drawing for cutting. The machining center can cut various thicknesses, angles and shapes. The advantages of this method are high precision, high speed and good cutting dimensional accuracy, which can be used for medium and small batch production. The disadvantage is that it requires certain equipment maintenance and operation technology.

In summary, in sheet metal processing, the choice of cutting process needs to be considered in combination with specific product design and production requirements. Various cutting methods have their advantages and disadvantages, and are suitable for different thicknesses, different models and shapes of sheet materials. It should be noted that safety precautions need to be paid attention to during the cutting process, and good maintenance and maintenance should be carried out to ensure the normal and healthy operation of the production line.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque