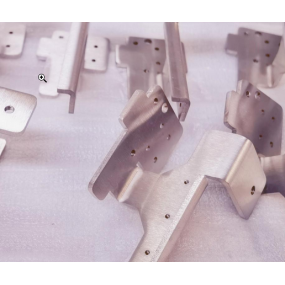

CNC numerical control centering machining is a commonly used precision parts processing method. Shenzhen EMAR Precision Technology Co., Ltd. has also cultivated many talents in centering machining over the years. Based on the custom machining and mass production of medical and communication parts, EMAR Precision Technology has developed the field of manufacturing precision parts for automobiles, drones and office automation. Because of its special structure, cnc numerical control centering machine has advantages that conventional numerical control lathes cannot match when machining some special parts.

Next, let‘s analyze the processing advantages of cnc numerical control centering machine from a professional perspective, and immediately enter the wonderful interpretation:

Next, let‘s analyze the processing advantages of cnc numerical control centering machine from a professional perspective, and immediately enter the wonderful interpretation:

A: CNC numerical control machine cutting process is relatively stable, in addition to the intermittent surface, under normal circumstances, the machining process of the lathe is continuous, not like planing and milling, in a process of cutting, the tool teeth have multiple cutting and cutting, resulting in conflict;

B: CNC numerical control centering machine is easier to ensure the accuracy of the workpiece when machining. During processing, the workpiece will rotate around a fixed axis, so that its surface has a unified axis of rotation. It is easier to ensure the concentricity of the machining surface and section.

C: CNC numerical control center machining tools can be shared with many numerical control lathes, manufacturing and grinding are more convenient, many experienced masters can independently grind the blade, so this is convenient for different parts of the angle requirements;

D: CNC numerical control machine can be applied to the precision machining of non-ferrous metals, most of the hardness of non-ferrous metals are low, such as aluminum alloy, copper alloy and other materials, plasticity is good, the use of other processing methods is difficult to obtain smooth surface;

D: CNC numerical control machine can be applied to the precision machining of non-ferrous metals, most of the hardness of non-ferrous metals are low, such as aluminum alloy, copper alloy and other materials, plasticity is good, the use of other processing methods is difficult to obtain smooth surface;

E: The cutting force is stronger, in short, it can be understood that the force of the ordinary numerical control lathe tool around the workpiece is different from the numerical control of the tool movement route, so when processing materials with strong hardness, it has higher processing precision, and the shaft core products that cannot be processed by conventional lathes can be easily processed by centering.

In fact, many friends who are engaged in heart machine processing will come into contact with a variety of precision hardware parts when they first start learning, and the products of domestic and foreign brands of numerical control heart machine are also slightly different, and overall there are great similarities. Shenzhen EMAR Precision Technology Co., Ltd. adopts imported numerical control heart machine brands Jinshang, Nomura, Star and other brands to process precision parts of aluminum alloy, stainless steel, carbon steel, copper alloy, pom, peek, Teflon and other materials with a size of φ 3mm~ φ 25mm.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque