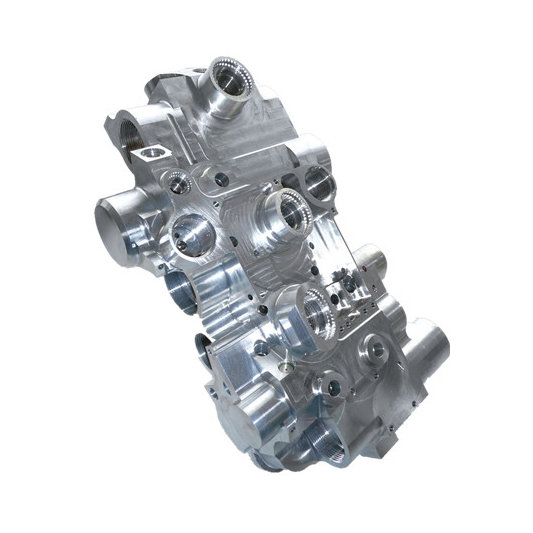

The principle of horizontal five-axis machining is mainly realized through a multi-axis machining center. It includes the main components such as the bed body, worktable, spindle, tool magazine and control system. The spindle is the core component of the five-axis machining center, which has high rotational speed and can be processed at high speed. The tool magazine is responsible for storing the tools, which can be automatically changed according to the needs to adapt to different machining needs. The bed body and worktable are fixed workpieces and support structure.  In horizontal five-axis machining, the spindle and the operation table can work together. The spindle can be installed on the bed table, which is set as the operation table of the bed body of the gantry machining center. People are accurately positioned as A arc, and the working range of A axis is from + 20 degrees to -100 degrees. At the same time, the B axis can be set as the rotary axis of the operation table of the bed body, which can be rotated within the range of 360 degrees. In this way, the cooperative work of the spindle and the operation table can realize the processing of multiple sides and directions in one clamping, and improve the machining accuracy and efficiency of the parts. In addition, the structure of the horizontal five-axis machining center can also be divided into three forms: XYZ + A + B, XYZ + A + C, XYZ + B + C. Among them, XYZ represents three linear coordinate axes, and A and B represent two rotating coordinate axes. The cooperative work of these coordinate axes can complete various complex parts processing, and avoid the occurrence of tool interference, overcutting and undercutting. Overall, the principle of horizontal five-axis machining is to achieve multi-faceted and multi-directional machining through the collaborative work of multi-axis machining centers, which improves the machining accuracy and efficiency of parts. At the same time, its structure and control system also ensure the stability and flexibility of the machining process.

In horizontal five-axis machining, the spindle and the operation table can work together. The spindle can be installed on the bed table, which is set as the operation table of the bed body of the gantry machining center. People are accurately positioned as A arc, and the working range of A axis is from + 20 degrees to -100 degrees. At the same time, the B axis can be set as the rotary axis of the operation table of the bed body, which can be rotated within the range of 360 degrees. In this way, the cooperative work of the spindle and the operation table can realize the processing of multiple sides and directions in one clamping, and improve the machining accuracy and efficiency of the parts. In addition, the structure of the horizontal five-axis machining center can also be divided into three forms: XYZ + A + B, XYZ + A + C, XYZ + B + C. Among them, XYZ represents three linear coordinate axes, and A and B represent two rotating coordinate axes. The cooperative work of these coordinate axes can complete various complex parts processing, and avoid the occurrence of tool interference, overcutting and undercutting. Overall, the principle of horizontal five-axis machining is to achieve multi-faceted and multi-directional machining through the collaborative work of multi-axis machining centers, which improves the machining accuracy and efficiency of parts. At the same time, its structure and control system also ensure the stability and flexibility of the machining process.

Hello! Welcome to EMAR's website!

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque