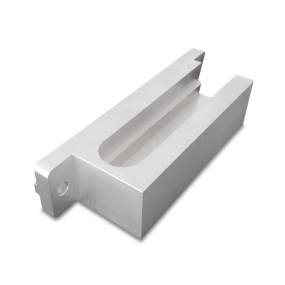

In a multi-station progressive continuous stamping die, the workpiece of the nail row machine is stamped down to complete the calendering and welding processes. But it still has a small part connected with the stamping sheet, and the stamping sheet carries the stamped and welded workpiece together into the ultrasonic surface treatment equipment to remove rust-proof grease and welding slag. The removal of welding beans and burrs is completed in the shot blasting chamber. This is necessary to avoid short circuits and electrical short connections when using the bent parts.

In the second short-term ultrasonic surface treatment, before the quality inspection of the bent parts, the ultrasonic surface cleaning technology is used again to remove the residues left by the shot peening treatment. After completing all the above operations, the bent parts are completely separated from the rough plate and stored together alone. The bent parts with poor quality of the nail machine are placed in the waste box, and the qualified bent parts are directly sent to the packaging workshop.  How to avoid damage to the bent parts during the production process, the following three are summarized for our reference:

How to avoid damage to the bent parts during the production process, the following three are summarized for our reference:

1. Transform the stamping equipment to improve the safety and reliability of production. There are many unsafe elements in the operation system and electrical control system of many outdated stamping equipment. If it is used continuously, it should be modified. Stamping equipment manufacturers should improve product design to ensure the safety and reliability of stamping equipment.

2. Equipment protection equipment. Because the production batch is small, it is necessary to equip safety protection equipment in stamping operations where neither automation nor safety stamping tools can be used to avoid injuries caused by operation errors. Various protective equipment have their own different characteristics and scope of use, and improper use can still cause injuries. Therefore, it is necessary to clarify the role of various protective equipment in order to achieve correct use and ensure safe operation.

3. Change the process, mold and operation method to complete the operation outside the manual mold. For large-scale production operations, you can start by changing the process and mold to complete mechanization and automation. For example, the use of automation, multi-station stamping machinery and equipment, the use of multi-tool and mechanized production equipment, and the use of continuous molds, composite molds and other combined processes. All of these can not only ensure the safety of stamping operations, but also greatly improve the production power.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque